While artificial intelligence and robotics are distinct concepts, they are intricately connected. Each aspect plays a vital role in the daily operations of various industries, ultimately contributing to making processes more efficient and optimizing internal procedures.

Encompasses a wide-ranging concept involving the application of acquired knowledge to execute tasks systematically, sans explicit instructions.

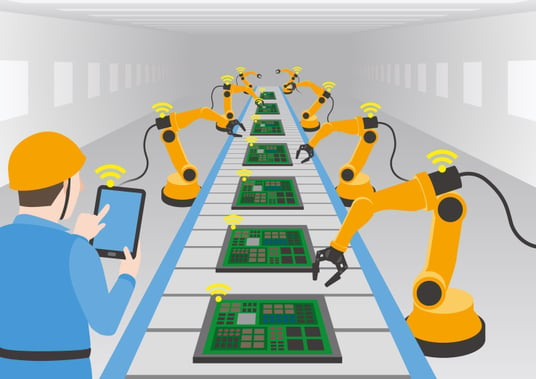

Robotics is a multidisciplinary field combining engineering, computer science, and other disciplines to create, develop, and control autonomous or semi-autonomous robots, programmable machines capable of performing tasks independently.

The intersection of technology and robotics? We delve into additional factors regarding every aspect and culminate in discussing potential future trends.

Key Variations and Commonalities

Automates tasks using technology, potentially incorporating robotics. Here is the improved text in a different style:

Embracing PC programming involves leveraging specific software programs to streamline business process management and constructively implement organizational systems.

Robotics focuses on the design, development, and programming of robots to perform specific tasks, which typically involve mechanical, electrical, and computer engineering principles. Robots have become ubiquitous in various applications, with examples including those specifically designed for assembling parts, as well as others tasked with cleaning tasks such as vacuuming floors and maintaining lawns through mowing.

Robotic systems and artificial intelligence can be employed independently or in tandem depending on the specific goals and objectives of a project or organization. As a result, each field presents comparable advantages that contribute significantly to the competitiveness of an organization, on par with those found in , , and.

What Is Automation?

By employing various technologies, including machines and expertise, to accomplish a task that would otherwise require the intervention of a human being. This thereby enables the employee to dedicate their time to more complex and forward-thinking initiatives.

The spectrum of calculators spans a wide range, from entirely mechanical devices to fully digital ones, and from straightforwardly simple to impressively complex.

Two fundamental principles:

Software is typically designed to perform tasks that are typically handled by humans on computer systems. There exist numerous branches, types, and variations of: cleverness, parentheses, and extras. The facility where artificial intelligence-powered robots efficiently manage and streamline repetitive digital tasks, seamlessly integrating with AI to optimize workflow. productivity and employee satisfaction.

involves potential automation with specific tools. It may well contain single machines doing autonomous tasks or a completely automated workflow. In today’s fast-paced industrial landscape, digitalization has become a crucial aspect of optimizing manufacturing processes. There are numerous types of.

-

Called stubbornly rigid, this concept involves the application of techniques aimed at persisting in a repetitive manner, remaining fixed in one place. In the automotive industry, a standard instance of fastening refers to a sequence of operations performed by technicians to secure components or parts together.

-

Permits for agility in manufacturing are enabled by software programs that can be reprogrammed or reconfigured to adapt seamlessly to entirely distinct products or processes. Unlike fixed programming, programmable manufacturing allows a robot to be reconfigured to modify the sequence of operations or process parameters as required.

-

enhances production efficiency by adopting innovative manufacturing approaches, thereby expeditiously meeting the dynamic demands of the marketplace. A highly flexible production facility can take the form of a manufacturing cell that produces digital components, where the cells are capable of adapting to changes in product design or demand for improved responsiveness.

-

Industrial 4.0, also referred to as Industry 4.0, leverages cognitive technologies, such as artificial intelligence, machine learning, and knowledge analytics to streamline and optimize manufacturing processes. Clever permits seamless autonomous decision-making, enabling real-time adaptation to adjustments within the dynamic manufacturing environment. A predictive analytics-based approach can utilize real-time sensor data and machine learning algorithms to forecast and prevent.

Advantages

Is focused on leveraging expertise to streamline tasks and enhance productivity. Automation involves using machines or technology to perform tasks that are typically handled by humans. By automating tasks typically handled by humans, it tackles numerous pressing concerns:

-

Finding, training, and retaining staff capable of delivering high-quality results has become increasingly challenging. By taking on these tasks, organizations don’t just reduce employee demand, but also empower staff to concentrate on more engaging and strategic activities, thereby fostering a stronger sense of commitment that may lead to increased job satisfaction and reduced turnover over time?

-

The current state of affairs regarding employee well-being and safety issues, which unfortunately leave workers vulnerable to harm. can forestall these security hazards.

-

Unlike humans, machines can operate continuously without experiencing fatigue while maintaining precision. Implementing this change will lead to enhanced productivity and diminished mistake rates.

-

Companies that successfully adopt this strategy reap significant rewards by optimizing efficiency, driving down costs, and delivering superior products of greater value.

The platform focuses on refining efficiency and accuracy within both the digital landscape and the professional arena.

What’s Robotics?

Robotics is a discipline within the broader field of engineering, concentrating primarily on the design, development, and application of intelligent machines that can perform tasks autonomously. Robotic engineering combines multiple fields to create, build, code, and operate sophisticated mechanical devices. These robots have the potential to revolutionize our work processes.

The primary objective of robotics is to mechanize tasks and streamline procedures. Despite its limitations, robotics is a specific area within engineering that concentrates on designing, building, and operating robots.

Sorts of Robots

Let’s explore three types of robots: industrial robots, service robots, and humanoid robots.

-

Are employed in factories and warehouses to automate tasks such as welding, machining, and material handling. Manufactured to deliver precision, pace, and repeatability, these machines often remain stationary. Robotic systems are highly flexible and can be easily reconfigured to perform a wide range of tasks. They are commonly deployed in industries such as printing, packaging, welding, machine tending, materials handling, and metalworking.

-

Used in various settings such as homes, hospitals, hotels, offices, airports, museums, and shopping centers, robots are employed for tasks including cleaning, welcoming visitors, and making deliveries. These robots are designed to collaborate with humans, typically being more affordable and less sophisticated than their counterparts. For instance, examples of such robots include robotic vacuum cleaners or lawn mowers, as well as interactive receptionists found in healthcare settings.

-

seem like human beings. Developed to harmonize with their surroundings like humans do, these advanced systems also feature lifelike facial expressions that can convey various emotions. An exemplary illustration of a humanoid robot, showcasing the union of advanced technology and anthropomorphic design principles. Sophia is equipped with advanced neural networks, enabling her to recognize and respond to human facial expressions, as well as discern subtle cues in gestures and emotions, thus facilitating effective interactions.

Robotics Advantages

Robotics has numerous benefits, including but not limited to:

-

These outputs – exact, making their output each correct and consistent. By implementing advanced algorithms and automation tools, they aim to significantly minimize human error.

-

Robots will not be impaired by fatigue or distraction, unlike humans, due to their design. This improves high quality assurance.

-

Unlike traditional labor, robots don’t require breaks or fixed working hours, allowing for uninterrupted production around the clock. Ensuring a high level of quality guarantees a significant reduction in waste and optimizes overall production yield.

-

Contrary to prevailing assumptions, robots are unlikely to displace jobs altogether; instead, they will generate new employment opportunities. As technology advances, freeing humans from mundane tasks, individuals are empowered to assume responsibilities where their skills and abilities can flourish and evolve more effectively. As technology advances, there is a growing need for skilled technicians, including engineers, IT specialists, and programmers, who can service and maintain robots, ensuring their efficient operation and integration into daily life. Professional development often yields a significant boost in employee job satisfaction and reduces turnover rates.

-

Engaging in reckless behavior on social media could have devastating consequences for your reputation. By allowing robots to handle arduous tasks, humans are relieved from the distress and hardship that would otherwise ensue.

Automation and robotics are poised to revolutionize various industries, driving transformative change across sectors.

What implications do you see the long-term trajectory of artificial intelligence having on the future of robotics? As various fields progress to revolutionize industries, introducing extra precision, effectiveness, and security to multiple processes, robotics is poised to transform existing industries and catalyze the emergence of new sectors alike.

Here are our predictions for emerging trends in AI and robotics:

-

Artificial intelligence systems are increasingly steady and capable of making themselves even more clever and adaptable. As the technological landscape continues to evolve, future robots are poised to transcend mere task automation; instead, they may possess the capacity to make informed decisions, analyze real-time data, and learn from their surroundings, thereby amplifying productivity and significantly reducing the likelihood of human error.

-

Cobots, short for collaborative robots, are designed to work harmoniously alongside human workers without the need for safety barriers. Conceived with security and versatility in mind, these devices are capable of executing a wide range of straightforward or complex tasks while maintaining an intuitive simplicity that enables non-experts to easily program and manage them. The adoption of these innovations is expected to accelerate across various sectors.

-

The versatility of robotics allows its software to seamlessly integrate across multiple industries, including agriculture, services, and more. Widespread adoption is likely to lead to a more uniform pace of development and innovation, ultimately driving financial stability and job creation in new markets outside.