The harmonic drive plays a crucial role in many robotic applications. Notoriously straightforward yet peculiar to behold, the gear mechanism boasts an astonishing degree of precision and a remarkable balance between torque and weight, despite occasional subtle fluctuations. So how does it work?

The Harmonic Drive gear’s unorthodox design is indeed a masterpiece, as its flexible ellipse within a circle configuration enables a wobbling movement that arises from the gentle rotation of two fundamental gears, only one-third of whose teeth engage at any given time, resulting in a remarkably compact and lightweight drive gear capable of delivering impressive torque with unwavering precision, free from any drive lash or play.

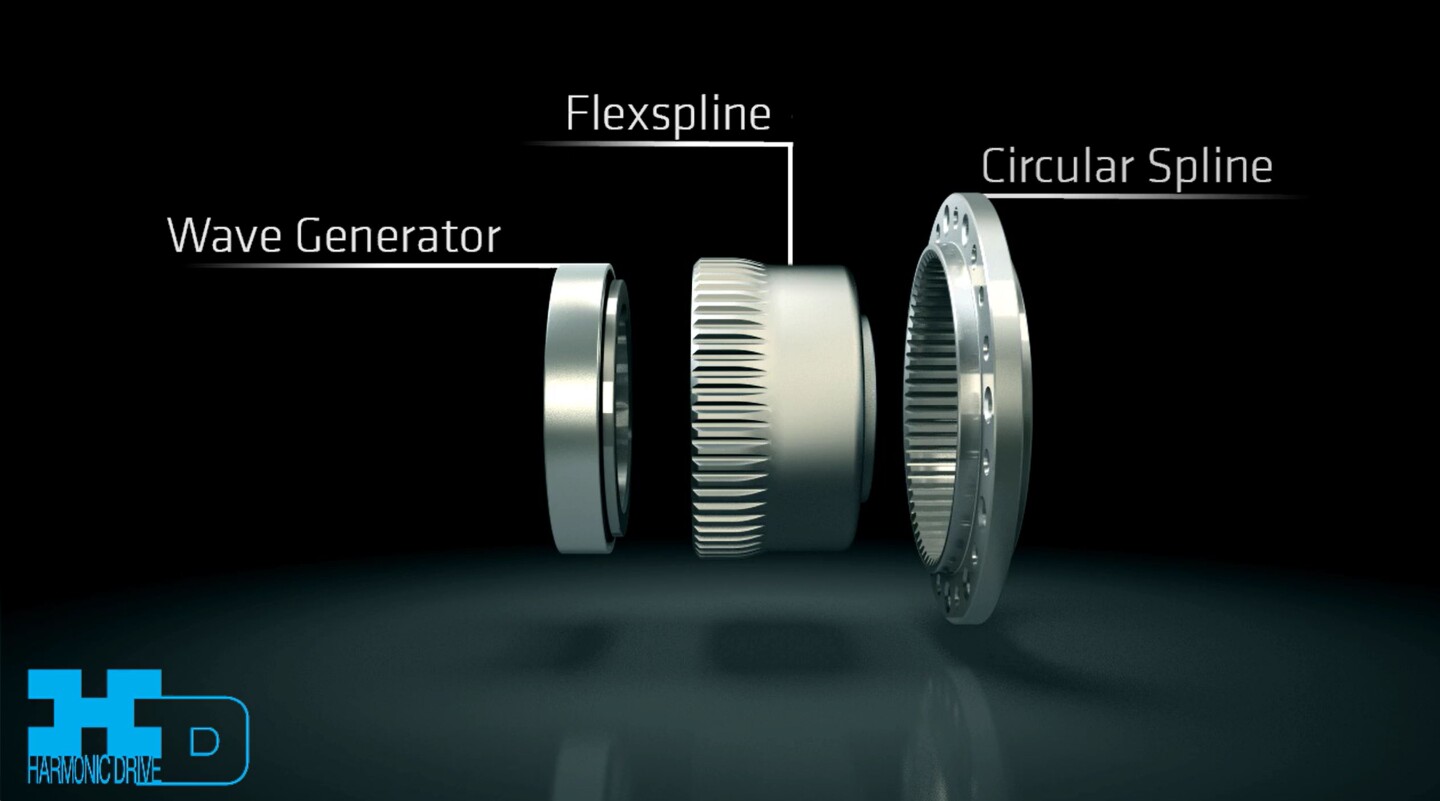

In 1957, Pennsylvania-based inventor, renowned for his innovative spirit and prolific patent record, which spanned a wide range of groundbreaking technologies including energy-efficient steering systems, recoilless rifle designs, and pneumatically triggered life jackets. In the early 1960s, the Harmonic Drive technology saw its first commercial applications. The product’s composition is comprised of three fundamental components:

Harmonic Drive

- The wave generator: A near-circular entrance hub featuring a ball-bearing race circumscribed about its perimeter.

- The flex spline: a versatile, cup-shaped component featuring a toothed periphery. When a rectangular wave generator is inserted, the device deforms radially while maintaining its torsional rigidity.

- The Round Spline: A rigid ring featuring internal teeth, analogous to a planetary ring gear, boasting two additional teeth compared to its FlexSpline counterpart.

As the wave generator rotates, approximately 30% of the flexspline’s teeth engage simultaneously with the corresponding teeth on the round spline, creating a continuous waveform. This causes the flexspline to rotate throughout the round spline, but in the opposite direction intended. Test it out:

What’s fascinating about Harmonic Drive’s innovative Pressure Wave technology?

This aspect of the methodology’s brilliance lies in its zero-backlash design, where gears possess no play or slippage, rendering it exceptionally well-suited for precise and high-quality motor control applications. This portable, lightweight design excels in situations with limited space. With minimal transfer components, the Harmonic Drive boasts exceptional reliability and ruggedness.

As we speak, harmonic drives are ubiquitous in numerous applications on earth, including industrial machinery, medical devices, aerospace systems, and even consumer products. off planet. Industrial robots, such as those from Fanuc and Kuka, are employed in tasks akin to welding and assembly, where precise and repetitive motion is crucial.

The robotic system, specifically crafted for minimally invasive surgical procedures, relies on Harmonic Drive technology within its articulated arms to provide precise and controlled micro-movements, eliminating any potential backlash for unparalleled accuracy throughout delicate operations performed on patients.

Harmonic Drive

Humanoid and quadruped robots utilize their legs and arms in various settings to achieve seamless, controlled movement while maintaining stability.

Despite being a space agency, even NASA’s Mars rovers rely on Harmonic Drives in the mechanisms of their robotic arms and wheels. The unyielding reliability of this design is aptly demonstrated by its ability to withstand the harsh conditions of extraterrestrial exploration, even in the face of abandonment without maintenance.

While Musser unfortunately passed away before witnessing his creation’s arrival on Mars, he nonetheless had the satisfaction of seeing it return home. The harmonic drive played a crucial role as a standard component of the Space Shuttle’s Distant Manipulator System, also known as Canadarm, used onboard orbiters such as Columbia and Challenger to manipulate payloads and deploy cargo effectively?

Seventy years on from its inception, the remarkable innovation endures, its unique and deliberate “wobble” remaining a defining characteristic as it finds new applications across diverse disciplines. From intricate surgical procedures to the farthest reaches of space exploration, the Harmonic Drive’s unparalleled brilliance stems from its uncomplicated yet robust design, unwavering dependability, and unmatched precision.

The Harmonic Drive pressure wave gear’s proprietary technology enables a unique advantage: zero backlash.

Supply: