For those examining the landscape, it is evident that robots hold a significant potential role in driving progress towards achieving the Sustainable Development Goals (SDGs). Despite its association with the physical realm, the sphere of spheres transcends mere spatial confines. As robotics optimizes various software for enhanced sustainability, it’s crucial to consider the supplementary costs or benefits across the entire supply chain? The externalities of employing robots to address this challenge encompass increased productivity by automating repetitive tasks, reduced labor costs through minimized workforce requirements, enhanced accuracy and precision, accelerated completion times, and improved worker safety by minimizing exposure to hazardous conditions. Moreover, robots can be designed to operate continuously without fatigue or breaks, thereby optimizing efficiency and reducing the need for overtime pay. Additionally, these machines can be programmed to work in environments that are inhospitable or too dangerous for human workers, thus expanding operational capabilities while ensuring employee well-being. Rise in innovation?

- energy prices

- manufacturing prices

- labor prices

- provide chain prices

- provide chain mileage

- uncooked supplies consumption

- and uncooked materials selection

Solving our global financial and environmental crises requires addressing current problems without introducing further complications? Here is the rewritten text:

It’s essential to move beyond initial approaches and examine how robotics can contribute to achieving global sustainability goals, addressing each juncture where robotics can make a meaningful impact.

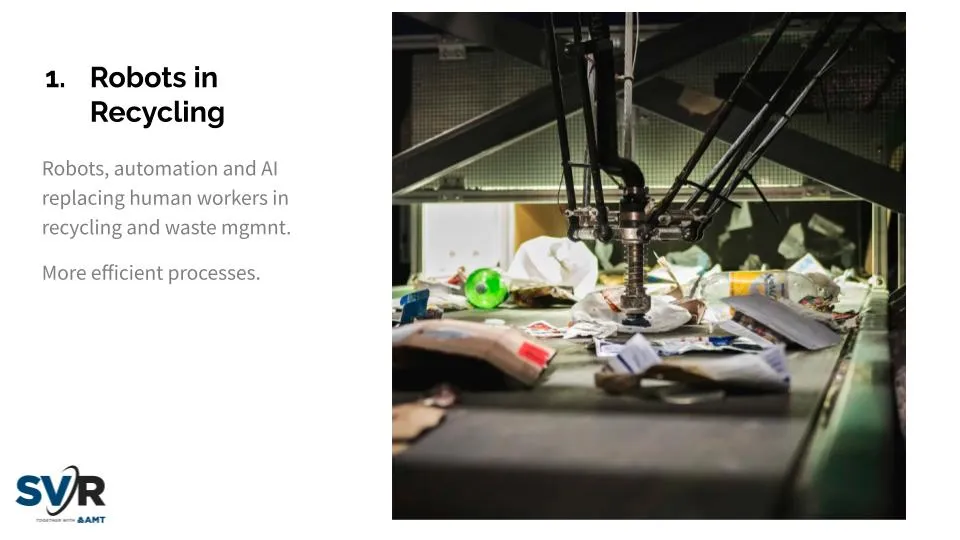

What opportunities exist in integrating robots into our current recycling processes to boost efficiency and sustainability?

Sustainability initiatives are being enhanced by simplifying existing processes to make them more environmentally conscious, cost-effective, and scalable. Making recycling higher.

Notable firms that exemplify a strong commitment to social responsibility include Amazon, Google, Patagonia, Starbucks, Unilever, and Walmart. Here’s a comprehensive overview of Fanuc’s cutting-edge technology.

According to JD Ambati, CEO of EverestLabs, the integration of artificial intelligence and robotic arms has led to a significant increase in crop yields, with some farms experiencing up to 30 percent gains compared to previous results. As a result, companies have been wasting tens of thousands of dollars on unnecessary waste disposal, but thanks to AI, they can now accurately quantify their losses and utilize robotic arms to efficiently collect and recycle materials.![]()

Robots are employed in various industrial applications, such as monitoring aquaculture systems or performing tasks like cleaning and maintenance for solar panels and wind turbines. If robotics expertise enhances and optimizes existing recycling methods, thereby increasing efficiency and reducing waste, then it has achieved a fundamental milestone in Sustainable Robotics – Degree 1.

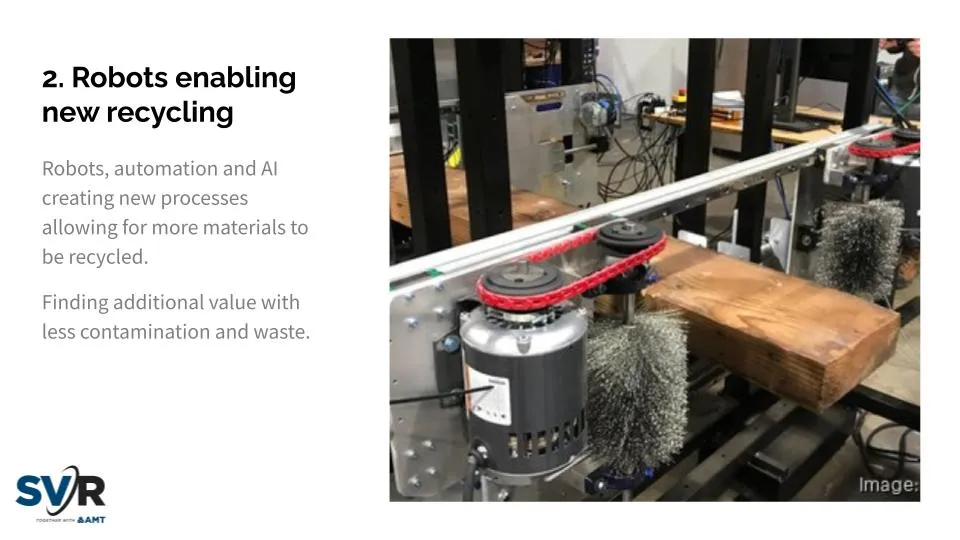

Can robots revolutionize waste management by streamlining recycling processes?

Is the facility designed to enable the recycling of robotic components and supplies, while also fostering innovation in emerging trade software platforms? One remarkable example is Timbercoast, a pioneering initiative that rescues reclaimed wood from dismantled buildings and reprocesses it into functional materials on an unprecedented scale.

Developments incorporating on-site resources and robotics-based 3D printing provide another example, as evident in the NASA-funded Habitat Challenge sponsored by SpaceX and Made In Space.

Another example is the ocean or lake being plagued by accumulating waste, with innovative solutions emerging like Waste Shark from Ocean Quest, a Quebec-based firm that deployed its robots in the Nice Lakes Plastic Cleanup, removing 74,000 plastic items from four lakes since 2020?

Serial Cleaners is poised to revolutionize beachside and marine cleanups by leveraging its innovative BeBot and PixieDrone technology, designed specifically for efficient and effective janitorial use in seashores, marinas, and golf courses, with the BeBot offering ample opportunities for prominent brand display. The tools developed as a direct result of the Great Lakes Plastic Cleanup’s (GLPC) initiative to tackle littering. The innovative system integrates distinct units, including the Seabin, a device that resides in water and extracts debris, and the Enviropod LittaTrap filter, specifically designed to capture waste in stormwater drainage systems.![]()

If a novel approach to monitoring recycling leveraging robotic capabilities emerges, it would likely fall within the scope of Level 2 innovation in sustainable robotics.

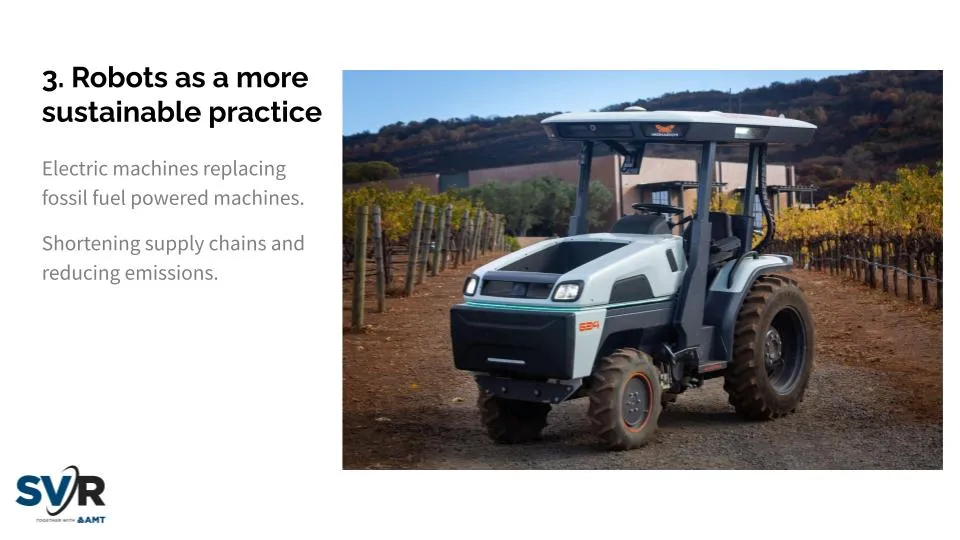

Will robots revolutionize our world by harnessing electricity from all sources?

One significant sustainability transformation facilitated by robotics is the shift away from fossil-fuel-powered transportation, logistics, and agricultural machinery toward battery-electric vehicle (BEV) technology. Small-scale autonomous electric vehicles’ increasing adoption can significantly reduce emissions while transforming the nature of journeys taken, particularly by decreasing the need for large vehicles that travel long distances at partial capacity.

The world’s first electric tractor has been developed, boasting a ‘driver non-compulsory’ design that enables either manual push-start functionality or autonomous operation, thereby providing farmers with greater flexibility in their operations. With the widespread adoption of laptop vision and AI in agricultural robots, sustainability is poised to receive a significant boost through the implementation of precision or regenerative agriculture methods that significantly reduce the need for chemical interventions. These advancements in agricultural observation are a significant milestone in the development of Degree 2 sustainable robotics, representing a substantial step forward in precision farming and agricultural innovation.![]()

While the development of compact, self-driving farm robots, such as those from companies like FarmWise, John Deere, and Small Robot Company, allows for reduced soil compaction and smaller, more manageable farm strips through precision farming practices. ![]() The advancements in sustainable robotics continue to propel us forward, with this being a significant milestone – Degree 3 of Sustainable Robotics.

The advancements in sustainable robotics continue to propel us forward, with this being a significant milestone – Degree 3 of Sustainable Robotics.

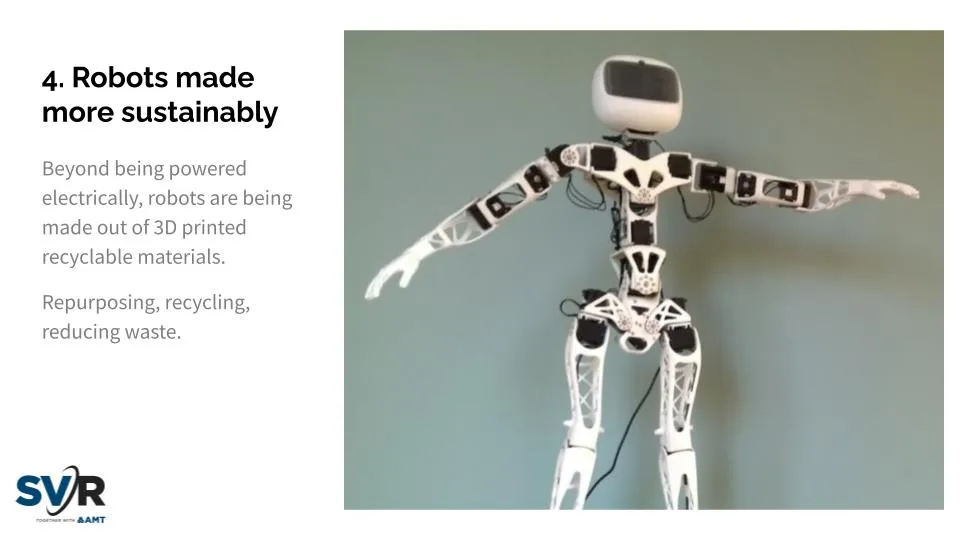

Degree 4: Robots

As sustainability levels escalate, designers delve increasingly deeper into the intricacies of robotic system development, refining their designs with precision. Transitioning to electrical energy from fossil fuels represents a crucial first step towards a more sustainable future. One alternative is switching to regionally sourced or produced supplies. Implementing recyclable materials in robotics is a crucial step towards achieving complete sustainability.

By maximizing the potential of 3D printing, they can efficiently manufacture and export robots to 47 countries worldwide, while also maintaining a local presence through regional production in Silicon Valley.

In a pioneering move, Cornell researchers Wendy Ju and Ilan Mandel have coined the term “Garbatrage” to describe the innovative opportunity to repurpose or fabricate robots by utilizing salvaged components from discarded consumer electronics, such as hoverboards.

“The timing couldn’t be more auspicious for a thorough examination of the impact of supply chain disruptions on sustainability efforts in light of recent global shortages and trade woes.” ![]()

This pioneering initiative exemplifies a prime example of advanced robotics technology, specifically Degree 4 of Sustainable Robotics, showcasing innovative advancements in the field.

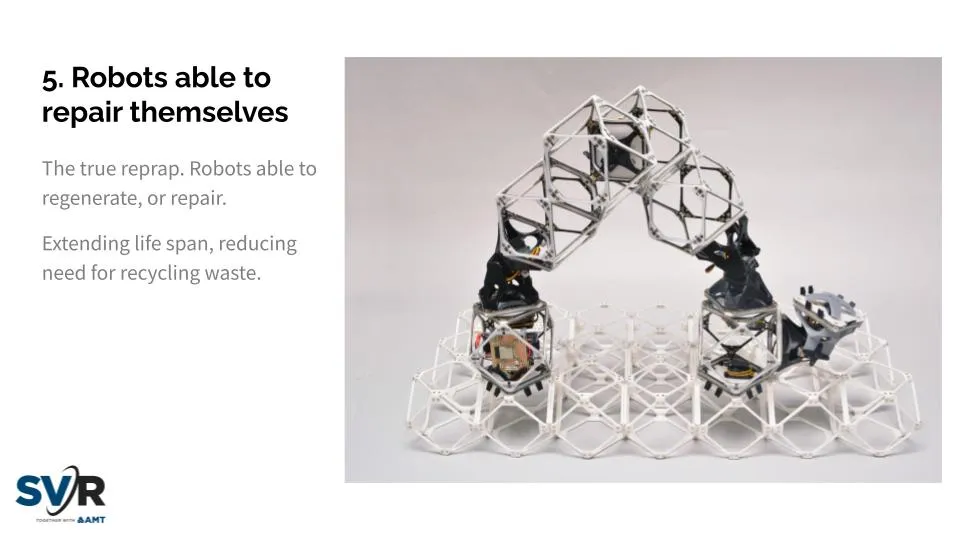

Degree 5: Self-powering/repairing Robots

Self-sustaining robots, capable of autonomous power generation, repair, and material recycling, represent the pinnacle of sustainable robotics – a true Degree 5 innovation. Here is the rewritten text:

The analysis reveals innovative solutions, such as the MilliMobile – a cutting-edge, autonomous robot that operates independently by harnessing power from harvested solar and radio frequency (RF) energy, effectively eliminating the need for batteries. What innovative education solutions are being pioneered by MilliMobile, conceived by the visionary Paul G.? Allen Faculty of Pc Science & Engineering, is the dimensions of a penny and might steer itself, sense its surroundings, and talk wirelessly utilizing power harvested from mild and radio waves.

It’s not simply analysis although. Within the past two years, a plethora of solar-powered agricultural robots has entered the market. Has developed a photovoltaic-powered spray robotic, which, in addition to being solar-powered, can also be recharged using wind energy.

By incorporating modular design into robotics, we can significantly reduce material waste and energy demands, as each module can be reused across multiple applications, eliminating the need for specialized robots with limited functionality. As innovative technologies such as self-powering and self-repairing emerge, they will enable robots to venture into previously inaccessible regions, including extraterrestrial environments, thereby reducing humanity’s dependence on grid infrastructure. As robots increasingly incorporate self-repairing capabilities, their product lifecycles are significantly enhanced. Here are the results:

The degree in sustainable robotics encompasses a multidisciplinary approach to the design, development, and operation of robotic systems that minimize environmental impact while maximizing societal benefits.

And sooner or later?

As companies prepare to thrive in the long term, several key assets are essential for transforming a typical organization into a sustainable robotics powerhouse. According to data from the International Trade Administration (ITA), the World Customs Organization, and the Organisation for Economic Co-operation and Development (OECD).

References

As Managing Director of Silicon Valley Robotics, he spearheads innovation; as founder of Girls in Robotics, he fosters diversity; and as a mentor, investor, and advisor, he empowers startups, accelerators, and think tanks to harness the transformative power of robotics and AI for socially beneficial purposes.

Andra Keay

As the Managing Director of Silicon Valley Robotics, he spearheads the organization’s efforts, while also serving as the founding father of Girls in Robotics, fostering the next generation of innovators. As a mentor, investor, and advisor to startups, accelerators, and think tanks, his guidance has had a profound impact on the industry. With an insatiable curiosity, he is driven to commercialize socially constructive robotics and AI, tackling pressing challenges and shaping a better future.