The most well-known and important example: Robots in medicine that accurately diagnose diseases and perform surgeries with precision, freeing medical professionals from routine tasks to focus on complex cases.

A prime example is medicine. Consider complex surgical procedures – even the slightest tremor or incorrect movement during an eye operation or minimally invasive intervention on the spine can have catastrophic consequences. Earlier, surgeons worked with extremely steady hands. Heute unterstützen Roboter diese Arbeit. For instance, there are operating systems where the surgeon controls the robot, but precise work – millimeter-accurate cuts and movements – is taken over by the machine.

These robots are equipped with advanced features that magnify and detail every aspect, enabling the surgeon to see exactly what’s happening. One could say that these robots possess built-in “loupes” – a visual system functioning like an extraordinary, superhuman vision aid. Through the combination of human control and machine precision, operations are possible that would be barely feasible for humans alone.

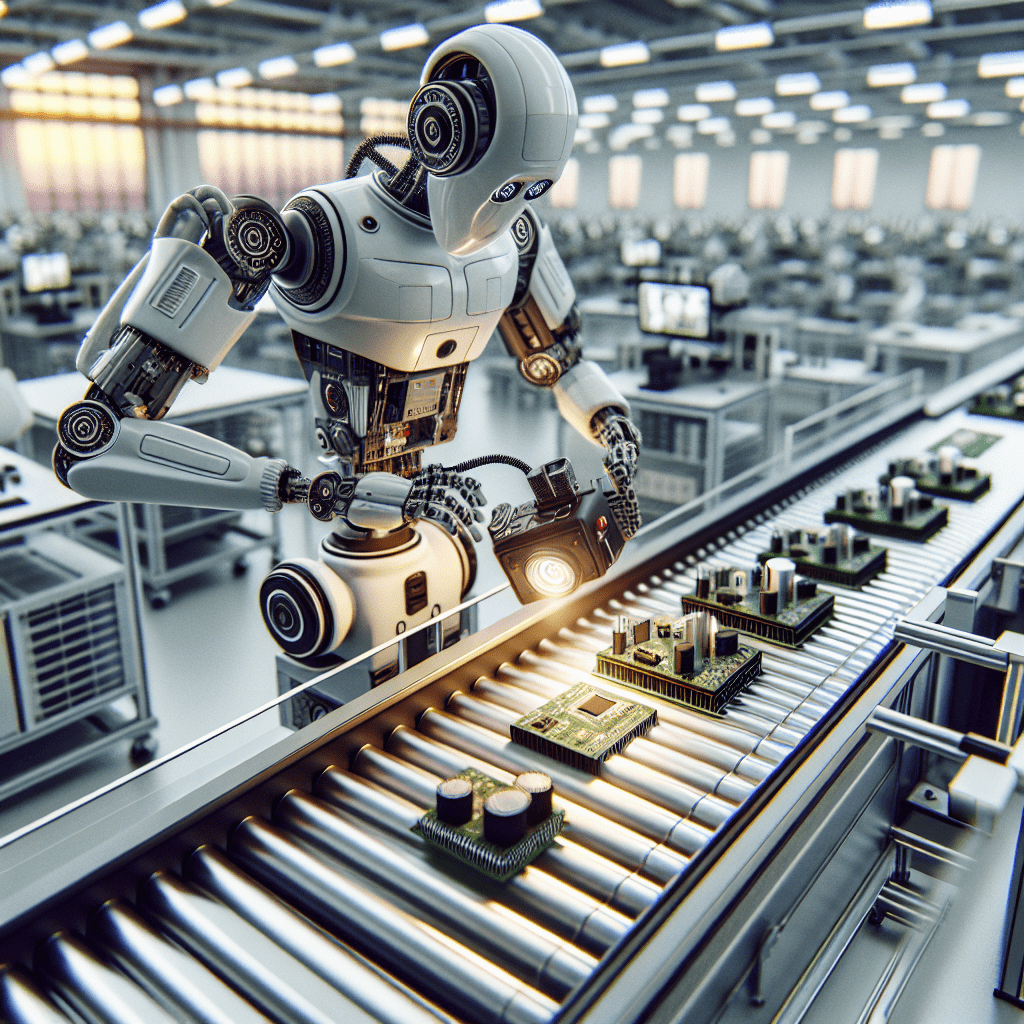

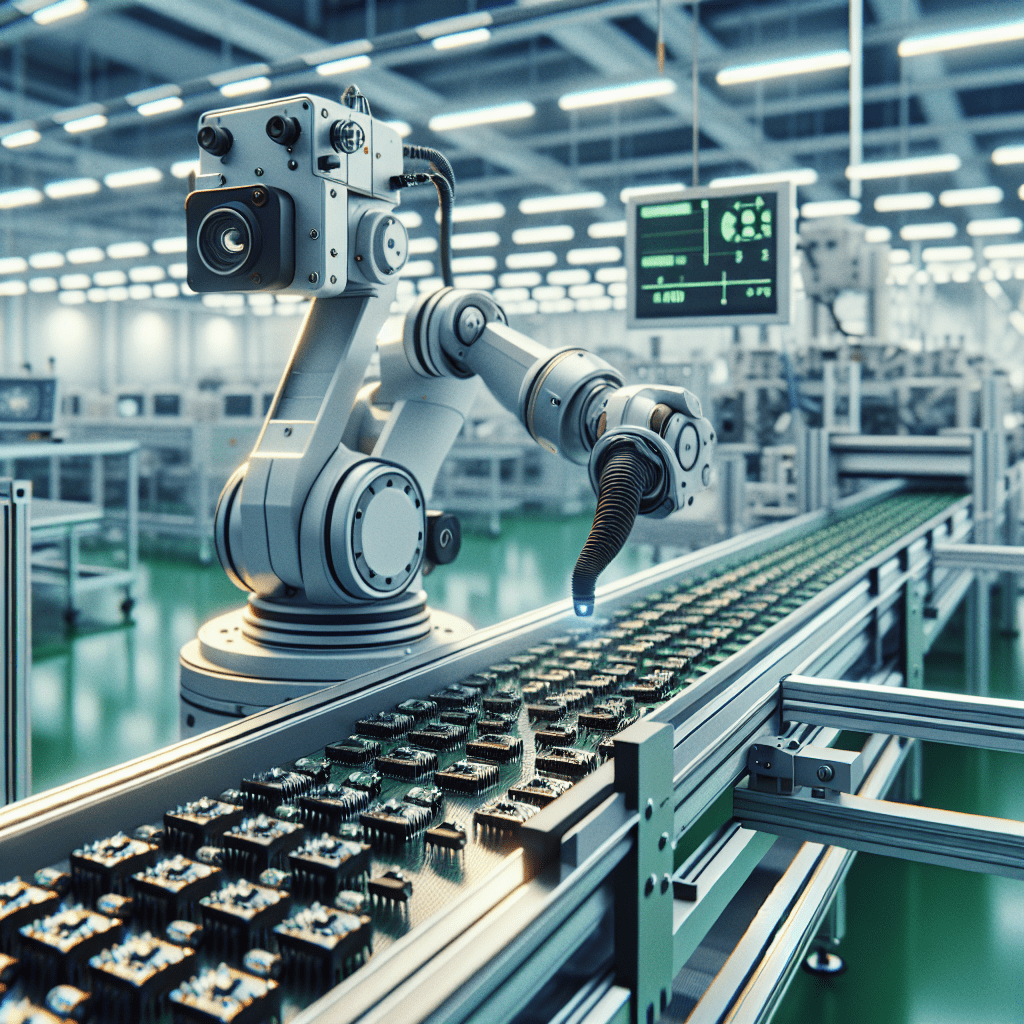

High-quality products from mass production lines inspected with precision.

Another example is industrial quality control. Earlier, people here often had the job of scrutinizing products on a production line with precision. Whether it’s tiny scratches on a glass screen or minuscule cracks in components – someone had to take a close look and decide if the part met quality standards? Magnifying glasses and specialized loupes were frequently employed here. In recent years, such inspection work is often handled by robots. These robots are equipped with high-tech cameras that can capture microscopic details. With the aid of AI algorithms, they can rapidly analyze whether a product meets the requirements or not?

Precise accuracy is particularly sought after in electronic production. Everyone is familiar with the sensation of a seamless and efficient computing experience, when devices like laptops or smartphones work flawlessly in sync – as well as the frustration that ensues when things don’t quite go according to plan. Tiny errors in these devices can easily go unnoticed when working solely with the human eye. Robots equipped with extremely high-resolution cameras can detect even the smallest errors in circuitry or solder joints. This high-tech magnifying glass sees everything, down to the minutest detail. The Episode: Fewer Errors, Higher Quality, Happier Customers?

Juwelierarbeiten mit kleinsten Teilchen

Robots with precision technology are also used in the field of jewelry production. Precision craftsmen once spent hours meticulously arranging tiny gemstones or engraving intricate patterns – a labor-intensive process requiring precise hands and keen intuition – but nowadays, robots are increasingly taking over this task. These machines can perform movements that are so consistent and repeatable, ensuring each piece is perfectly processed. The machine does not replace the artistic creativity of goldsmiths, but it assists in the precise and intricate steps that require great skill.

What’s fascinating is that robots not only bring greater precision but also alleviate the human burden. Tasks demanding high concentration and sharp attention often prove exhausting and necessitate pauses to maintain quality. Unlike humans, robots can work for hours without interruption and consistently deliver the same high level of precision. By automating tedious and monotonous tasks, you can free people to focus on more creative and strategic endeavors.

In summary: As robots and AI increasingly take on tasks requiring precision and accuracy, once-demanding tasks such as those relying on keen eyesight and human intuition are being usurped by automation. In medicine, industry, or jewelry production: machines and their “built-in” lenses do astonishing work and simultaneously relieve us. While this sentiment is true, one could argue that robots elevate human capabilities in terms of precision and efficiency, rather than replacing humans altogether.

bezahlter Gastbeitrag von AWISEE