Researchers at the University of Potsdam are exploring the application of artificial intelligence in production management through a factory simulation using Fischertechnik’s manufacturing facility simulator.

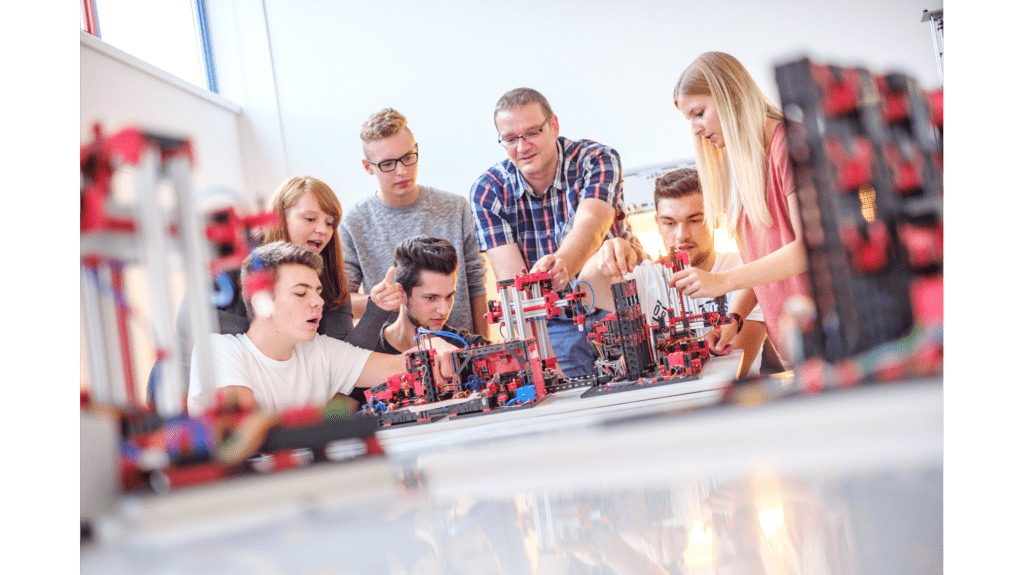

As a leading expert in the field of business informatics, Marcus Grum serves as a junior professor, focusing on AI-based application systems. He bends over a roughly one-metre-tall model constructed from Fischertechnik building blocks. Enthralled, he watches as a red wooden beam is transported from a small high rack storage to various manufacturing facilities via conveyor belts. The FischerTechnik simulation model is employed by universities and training institutions to depict the order process, production process, and supply chain processes in digitally interconnected steps, thereby facilitating a comprehensive understanding of logistical operations.

At the University of Potsdam, the fisheries technology Lernfabrik 4.0 was utilized in combination with other simulation tools and a neural twin to refine global manufacturing control processes. In a research series, for instance, a jam production simulation was conducted. It was assumed that products were manufactured globally at four distinct production facilities, each equipped with varying IT systems.

Were all processes illuminated, from procuring the fruits to delivering them to the customers. The Fishertechnik Learning Factory 4.0 represented one of four interconnected haptic manufacturing stations. The process within the annex began with fruit storage, followed by feeding it into a cooking machine for jam production, and ultimately concluded with filling glass containers.

das Ausliefern der Produkte simuliert. The haptic model was integrated with a synthetic neural community (SNC), a type of artificial neural network. By conducting trial series and experiments, we obtained valid results and highlighted production inefficiencies. By analyzing these findings, we can infer how to avoid such inefficiencies, explains Professor Grum. A young scholar was honored last year by the Werner-von-Siemens-Ring Foundation for developing a methodological approach that enables the modeling of machine and business processes using artificial neural networks.

Future research will focus on the empirical verification of neural network instructions and corresponding management interventions that emerge in real-time production settings. “The fischertechnik factory simulation system will also be used here,” says Professor… Grum.

Detailed information on the FISCHERTECHNIK factory simulation systems?