Developing highly efficient photovoltaic cells, transistors, LEDs, and batteries demands innovative materials with unique compositions that remain to be discovered.

Scientists are accelerating the search for high-performance materials by leveraging AI tools to identify top prospects from an enormous library of chemical compositions, comprising hundreds of millions of potential formulas. Engineers are working in parallel to develop machines capable of printing multiple fabric samples simultaneously, leveraging AI-tagged chemical compositions as the basis for their creation.

Despite previous efforts, there has been a lack of a similarly swift method to verify whether these printed materials actually perform as expected. The last stage of fabric characterization has proven to be a major hindrance in the efficient screening of premium materials.

MIT engineers have devised a pioneering laptop vision strategy that dramatically accelerates the identification of novel digital materials following synthesis. The approach employs mechanical analysis of printed semiconductor sample photographs, swiftly estimating two critical digital parameters per pattern: band gap, a metric of electron activation potency, and stability, a gauge of durability.

The innovative methodology accurately categorises digital materials at a lightning-fast pace of 85 times faster than traditional industry standards.

The researchers aim to expedite the search for viable photovoltaic materials by leveraging this innovative approach. They intend to integrate this methodology into a fully autonomous supplies verification platform.

According to MIT graduate student Eunice Aissi, their ultimate goal is to transform the system into a self-sufficient, long-term laboratory facility. “The proposed system allows us to furnish a PC with advanced computational tools, enabling it to anticipate potential compounds, followed by continuous production and characterization of these predicted materials until we achieve the desired outcome.”

“A range of appliances is supported by these strategies, from amplifying solar power to clearing electronics and transistors,” says MIT graduate student Alexander “Aleks” Siemann. While it covers a range of possibilities, the statement could be clarified. Here’s one way to rephrase it:

“This scope encompasses the full spectrum of ways in which semiconductor supply chains can positively impact society.”

Aissi and Siemens introduce a groundbreaking new approach. The researchers, including MIT co-authors Fang Sheng, a graduate student, Basita Das, a postdoctoral fellow, and Tonio Buonassisi, a professor of mechanical engineering, as well as former visitors Hamide Kavak from Cukurova University and Armi Tiihonen from Aalto University.

As soon as a novel digital material is synthesized, its properties are typically characterized by an expert who meticulously examines one property at a time using a benchtop spectrophotometer, such as UV-Vis, which scans various wavelengths of light to pinpoint where the semiconductor exhibits increased absorption. While the conventional approach yields precise results, it remains a labor-intensive process: A site professional typically examines around 20 material samples per hour – a pace slower than many printing devices that can produce 10,000 unique material combinations per hour.

“The characterization course of the guide may be extremely slow,” Buonassisi states. “They promise unparalleled precision in measurements, yet their pace lags woefully behind the demands of today’s rapid material deposition.”

Researchers sought to accelerate the characterisation process and alleviate a major bottleneck in sample screening by harnessing the power of computer vision – a field that leverages laptop algorithms to swiftly and automatically interpret visual features within an image.

Energy abounds in optical characterization strategies, observes Buonassisi. Data can be quickly obtained at any moment. “There exists a profound richness in photographs, encompassing numerous pixels and wavelengths, that exceeds the capabilities of human processing but is within the purview of a computer’s machine-learning program.”

The staff discovered that fundamental digital properties, such as band gap and stability, can be reliably predicted solely from visual data, provided it is collected with sufficient detail and correctly interpreted.

Researchers have created two novel laptop vision algorithms capable of automatically interpreting images of digital materials: one estimating bandgap, and another determining stability.

The primary algorithm is engineered to extract visible data from highly detailed, hyperspectral images.

“Hyperspectral images differ fundamentally from traditional digital cameras, which capture scenes in just three color channels – red, green, and blue (RGB),” Siemens explains. “In contrast, hyperspectral pictures boast an astonishing 300 channels.” The algorithm processes this data, undergoes transformations, and calculates a band hole. “We completed that course at an unusually rapid pace.”

The second algorithm scrutinizes normal RGB photographs to evaluate a fabric’s stability by detecting subtle changes in its colour over time.

Researchers have found that changes in colouration serve as a reliable indicator of degradation costs within their study’s material system, notes Aissi.

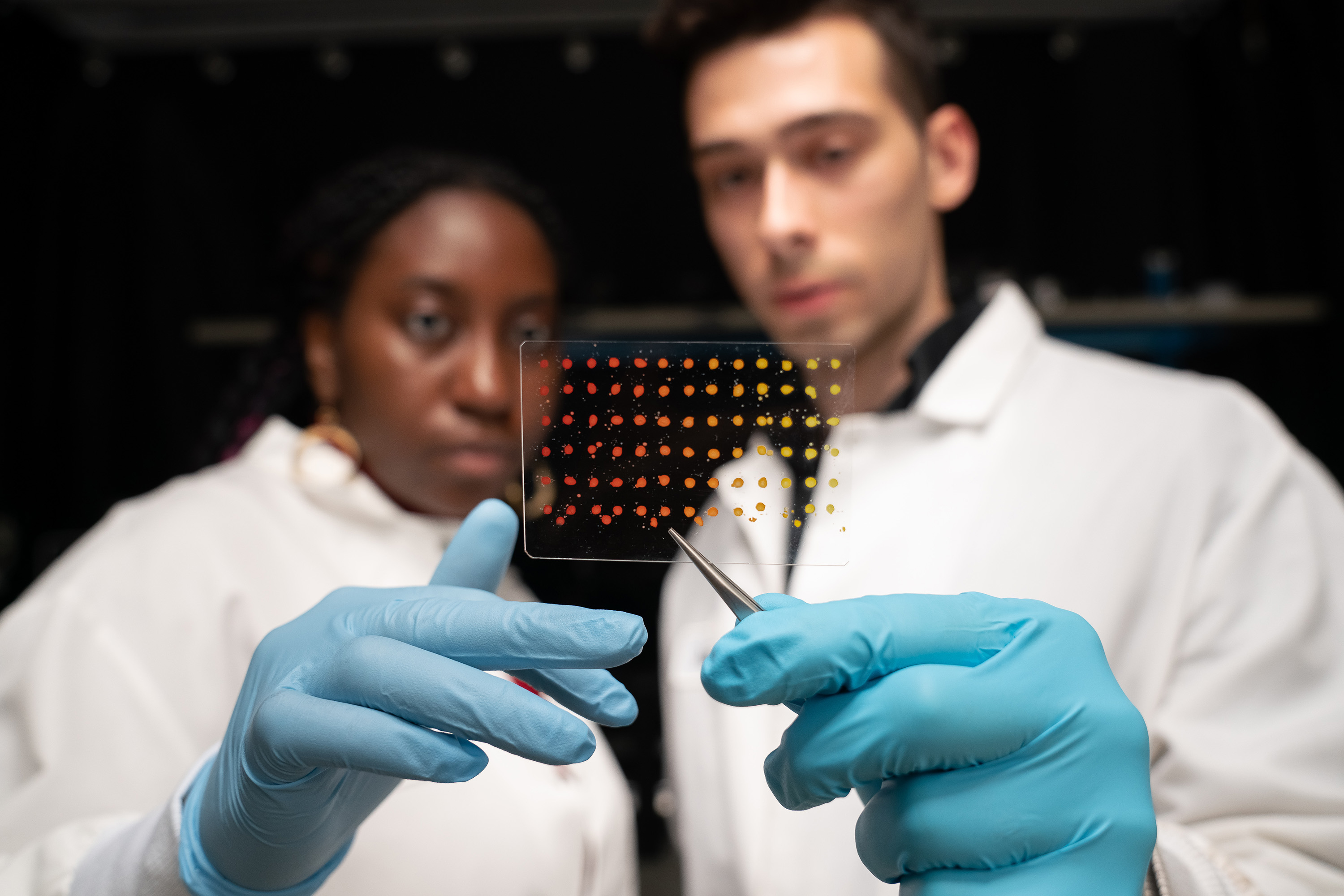

The research team employed the two novel algorithms to investigate the band hole and stability in approximately seventy printed semiconducting samples. Using a robotic printer, researchers deposited multiple samples onto a single slide, much like placing cookies on a baking sheet. Each deposit was created using a distinct blend of semiconductor materials. Researchers fabricated distinct proportions of perovskite materials – a versatile material poised to revolutionize solar cells due to its exceptional efficiency, yet notorious for its rapid degradation rate.

“People are trying to modify the perovskite’s composition by adding small amounts of various substances in an effort to enhance their stability and performance,” Buonassisi notes.

The researchers promptly printed 70 distinct perovskite compositions onto a single substrate, following which, the team employed a hyperspectral digital camera to meticulously scan the entire surface. Utilizing an algorithm that visually segments the image, the system mechanistically separates the samples from the surrounding environment. The team executed a cutting-edge band hole algorithm on a selection of remote samples, systematically calculating the optimal band holes for each unique pattern. The entire bandhole extraction process took approximately six minutes.

According to Siemenn, manual characterization of the same volume of samples typically takes a site professional several days to complete.

To assess stability, the team placed an identical slide in a controlled chamber that allowed them to differentiate between various environmental factors, such as humidity, temperature, and exposure to light. Using a standard RGB digital camera, they captured images of the samples every 30 seconds for a duration of two hours. Utilizing the second algorithm, they analyzed images of each pattern’s evolution over time to quantify how each droplet’s colour transformed, or deteriorated, under various environmental conditions. The algorithm yielded a stability index, quantifying the robustness of each pattern’s structure.

As an examiner, they compared the staff’s results to guide measurements of the same droplets, taken by a site professional. Compared to the professionals’ benchmark estimates, the staff achieved outstanding accuracy, with band hole and stability outcomes matching expectations at 98.5% and 96.9%, respectively, while also delivering a remarkable 85 times faster processing speed.

“We’ve been astonished by the algorithms’ capacity not only to accelerate material characterization but also to produce accurate results,” Siemenn says. “We envision this process slotting seamlessly into our existing automated materials pipeline in the lab, enabling us to run it entirely autonomously, leveraging machine learning to guide where we want to discover new materials, printing them, and then characterizing them at unprecedented processing speeds.”

This research was partially funded by First Photovoltaic.