In this tutorial, I will demonstrate how to leverage Blackbox logs to optimize filter settings and PID tuning for a Betaflight-based FPV drone. By leveraging PIDToolBox as a primary tool for filtering and PID tuning, I can then supplement this effort with Blackbox Explorer as a secondary device for implementing feedforward control and routine troubleshooting.

This material is intended solely for informative purposes. The creator assumes no liability for any damages resulting from actions taken by readers in reliance on the content provided.

By providing a comprehensive understanding of the drone’s dynamics, this feature empowers users to fully harness its capabilities. Noise filtering issues and minor overshoots are uniquely prevalent in Blackbox exclusively. Are you a perfectionist or someone who thrives on fine-tuning details? If so, this comprehensive guide is designed specifically for you.

For those unfamiliar with Blackbox, we recommend taking a glance at.

After dedicating more than 200 hours to crafting a comprehensive 8000-word tutorial. If you find my content valuable,

To optimize performance using Blackbox data, our goal is to achieve two key objectives:

- Minimize filtration to balance speed and noise levels effectively.

- The drone’s flight trajectory must be precisely controlled and responsive to pilot inputs.

- Install a sturdy FC stack featuring high-quality rubber grommets (gummies) designed to minimize noise disturbance while ensuring maximum stability.

- When assembling the FC stack, utilize steel screws exclusively, avoiding the use of nylon or plastic alternatives, which are prone to failure and vibration-related damage. When seeking a spacer solution, consider opting for discreet and gentle silicone options instead. By switching to lighter titanium screws, you can shave off a few precious grams.

- Secure the stack screws tightly using a steel nut before mounting the 4in1 ESC. When your body has inserted nuts, you typically don’t need additional ones. Initially, tighten screws manually, followed by a final adjustment using a wrench or screwdriver.

Utilize four sturdy plastic fasteners to securely hold the FC stack in place. Tighten the nuts by hand alone to avoid over-torquing and potentially crushing the gaskets, allowing the mounting system to function optimally.

1.

Configure the following options in the Blackbox settings:

* Under the ‘Audio’ tab, set the ‘Sample Rate’ to 44.1 kHz and the ‘Bit Depth’ to 16-bit.

* In the ‘Effects’ section, select the ‘Reverb’ option with a room size of 10 feet and a decay time of 2 seconds.

* Set the ‘Master Fader’ level to -20 dB and the ‘Mute’ button to the off position.

- Onboard Flash or SD Card

- Up to 2 kHz (or 1.6 kHz for the BMI270 gyro),

- GYRO_SCALED (information unfiltered gyro sign)

- To optimize memory usage during extended recording sessions, consider disabling redundant data streams such as altitude, GPS, and magnetometer readings, and instead stick with the default settings.

2. Disable the in your OpenTX/EdgeTX radio (System -> {Hardware}) to cut back latency.

3. :

I’ve a submit explaining the . Here are the five drones that make up our comprehensive fleet:

For BLHeli_32 ESC:

- 30%

- 24

- The audio sample rate should be set between 44.1kHz and 192kHz; however, since the specific rates you provided are mentioned (LOW at 24kHz and HIGH at 48kHz), it can be revised as follows:

Set SAMPLE RATE to 24kHz LOW and 48kHz HIGH. While 48kHz may be a suitable choice for reducing gyro noise, ensuring a smoother and more straightforward tuning experience for your quadcopter. While 24kHz enables greater braking energy, enhancing prop wash management and responsiveness, it also increases the risk of unwanted vibration. When faced with a dilemma, consider opting for the tried-and-true standard of 48 kHz.

To enable bidirectional DShot communication on a BLHeli_S ESC, flashing Bluejay is necessary for the implementation of RPM filtering and Dynamic Idle features. Here’s the improved text:

You’ll find detailed instructions on how to flash your device in this section.

3. Depart from PID/filter settings at their default. Permit seamless access to the entire array of sliders and options on the PID Tuning webpage within the Betaflight Configurator.

Configure the PID loop frequency within the Configuration tab, and specify the ESC protocol in the Motor tab.

Allow users to adjust motor settings directly within the motors tab.

Many modern ESCs enable bidirectional DShot capabilities. I’ve a tutorial on . While BLHeli_32 ESCs perform well outside of their intended field, users of BLHeli_S ESCs must take an additional step initially.

Verify whether the system is functioning properly by operating the motors within the Motors tab without propellers, ensuring that the error rate (E) remains at 0% throughout. Attempt slower D-Shot protocols, such as D-Shot 300 or D-Shot 150, instead. If issues continue to arise, you may need to accept the limitations of bi-directional DShot and RPM filtering.

Upon enabling, navigate directly to the PID Tuning tab, followed by the Filter Settings section, where you can permit the Gyro RPM filter – a highly effective filter featured prominently in Betaflight.

5. Load the suitable RC_Link preset.

Diverse remote control (RC) linkages necessitate tailored RC smoothing and feedforward settings. Inadequate configuration settings may lead to issues of stuttering and vibrations. My go-to choice for reliable remote control hyperlinks is ExpressLRS.

Loading the pre-configured RC_Link preset in Betaflight simplifies the process of applying necessary settings automatically. Choose your flying style based primarily on personal preference; for many, Freestyle is the way to go.

To optimize Crossfire performance, freeze the packet frequency at either 50Hz for more varied data transmission and slightly higher latency or 150Hz for reduced latency and minimal variance via the TBS Agent Lite’s LUA scripting capabilities.

6.

In the PID tuning tab, adjust the TPA breakpoint from 1350 to 1750 to avoid obscuring oscillation points during low- and mid-throttle tuning and ensure a more accurate calibration process. When oscillation points occur at high throttle levels, it’s essential to fine-tune the throttle position adjustment (TPA). Nevertheless, I generally recommend minimizing TPA usage whenever possible.

You can effectively utilize integral action (I) and derivative action (D) in your PID controller and filter tuning.

The PID Toolbox is a game-changer, standing out as the most powerful and effective black box tool in its class. By evaluating log entries on a facet-by-facet basis, you can more easily identify the effects of your filtering decisions. When utilizing control strategies, the Step Response device proves valuable in refining Proportional-Integral-Derivative (PID) settings. The spectral analyzer at PTB employs decibel units on the Y-axis, thereby providing more accurate and meaningful comparisons. The PTB framework also provides accurate estimates of filter delay, a valuable feature that can significantly enhance system performance.

Although PTB might be slower and less intuitive compared to using Blackbox Explorer. For rapid issue identification or troubleshooting a solitary log, BE proves to be faster and more straightforward. While traditional methods serve their purpose, PTB (Pulse Train Buffering) remains the gold standard for noise and filter tuning.

Within the Betaflight application, you’ll discover the entire collection of filters located in the PID Tuning tab. Mastering these tutorials requires confidence in navigating the various settings. Today, we’ll focus primarily on the novice areas – RPM filter and Dynamic Notch – and adjust the orange-colored Gyro and D-Time Lowpass Filter sections using the sliders. I’d rather not meddle with the delicate petals either.

Additional studying:

High-quality hardware can significantly reduce the need for sophisticated filtering mechanisms. Ensure a seamlessly integrated body design featuring strategically positioned resonance points, precision-crafted propellers that harmonize for optimal performance, and durable motors equipped with smooth-bearing systems.

- Maintain optimal altitude by employing a gentle reduction in thrust, accompanied by subtle adjustments to the control stick.

- Gradually increase engine throttle to maximum power output within a timeframe of approximately 5-10 seconds. The test demonstrates vibrational phenomena across various throttle ranges and body resonance frequencies.

- Following a brief sequence of throttle manipulations, bring the aircraft to a safe touchdown and initiate disarming procedures.

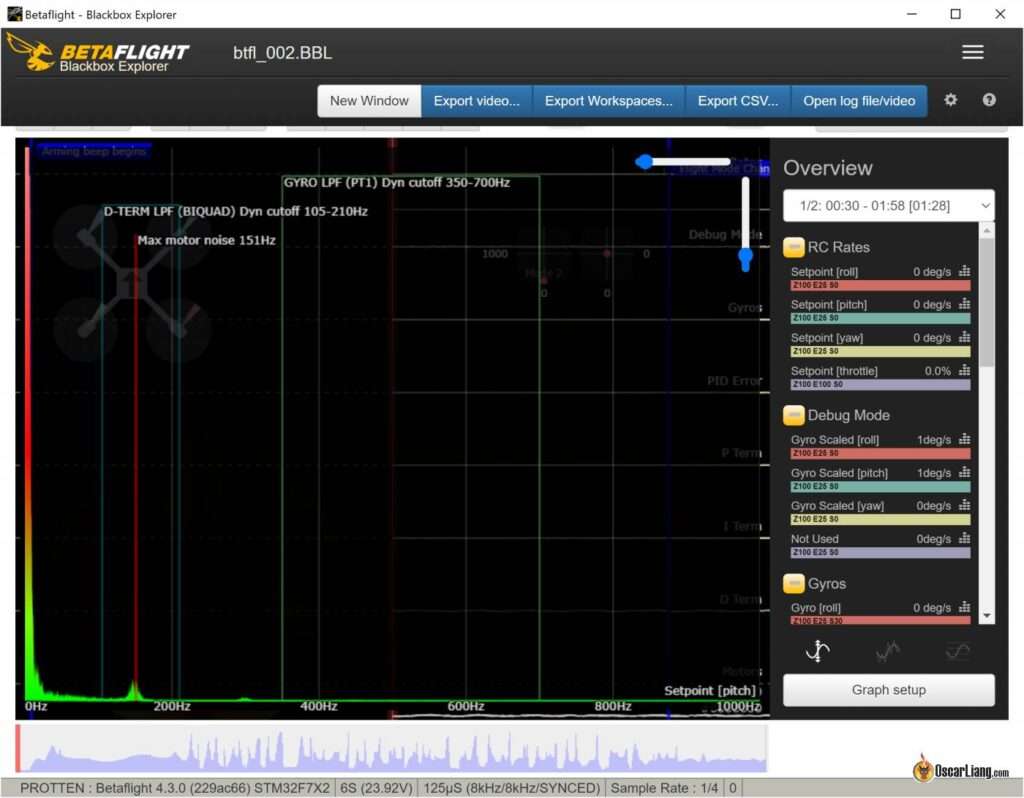

This is what a typical throttle sweep log might resemble: consult the underside bar for throttle adjustment settings.

Upon opening the Throttle Sweeps log in BlackBox Explorer, select the “Gyro_Scaled” option from the Precise Hand pane, revealing the raw, unfiltered gyro signal. I urge i and o to remove takeoff and touchdown components from the log.

The accompanying graph depicts the raw gyro signal frequency data extracted from a standard 5-inch FPV drone.

- Drone flight actions.

- Aerodynamic disturbances caused by inadequate proportional-integral-derivative (PID) control, faulty electronic speed controller (ESC) configurations, and hazardous radio control (RC) link settings, among other issues?

- Body resonance or free components.

- Noise from motors and propellers, as well as their inherent harmonics.

The subtle nuances of drone flight are evident in frequencies below 20Hz, indicating a harmonious response to controller inputs.

Between 20Hz and 100Hz lies the range where undesirable vibrations, akin to oscillations and prop wash, typically occur. Normally, one would aim to observe minimal variation in exercise on this frequency? While having some consistency is normal, an excessive quantity implies an oscillation that demands attention to rectify the imbalance. Usually, we strive to filter out frequencies below 100Hz because these represent genuine movements of the drone that we either want to accommodate or counteract. However, filtering on such low-frequency variability can potentially exacerbate problems by introducing considerable latency. Analyzing the spectra beneath 100 Hz can provide insight into vibration patterns and mid-throttle oscillation points, as well as how effectively the helicopter copes with prop wash.

Since we’re primarily focused on the low-end frequencies, we disregard any signals above 1 kHz, as they minimally affect our drone’s performance. We aim to focus our attention on eliminating interference within the frequency range of 100 Hz to 1000 Hz.

While not immediately obvious, excessive filtering can inadvertently generate oscillations that manifest as noise in frequency ranges below 100 Hz. The filtering process causes a noticeable delay. As the quad attempts to correct the mistake, a delayed reaction may result in an inadequate response, potentially exacerbating the issue. It would likely exacerbate the issue, causing a self-reinforcing feedback loop that would induce oscillations in the drone’s flight path, potentially leading to instability and loss of control.

However, reducing filter constraints allows low-frequency noise points under 100Hz to potentially increase in response to decreased latency and the quad’s faster reaction to correct PID errors. By employing reduced filtering, you can amplify PID advantages, resulting in a more accurate quadcopter that maintains its setpoint with greater stability and effectively combats prop wash effects.

By examining the gap between the original Gyro signal and its filtered counterpart, Gyro_Scaled, you can quantify the significant time lag introduced through the filtering process.

In PTB, the system automatically calculates the latency resulting from gyroscopic and D-term filtering, as depicted in the top-right corner of the first graph’s second column.

I employ a standard filtering protocol that commences by eliminating motor noise frequencies via RPM filters, followed by the suppression of body resonances through the application of dynamic notch filters, ultimately culminating in the attenuation of ambient noise floor levels utilizing Gyro and D-term low-pass filters. Can I be tuning filters on this order:

To minimize latency, we aim to utilize minimal filtering while still ensuring adequate filtering to prevent motor damage during returns with a bent prop. While applying excessive filtering might ensure security, it also renders the drone inert and unresponsive due to the prolonged latency. The additional installation of those exhaust fans may further exacerbate the propensity for prop wash to develop. We must strive for stability at all costs.

Aside from examining Blackbox logs, motor temperature serves as another valuable metric for fine-tuning filters. When motors become excessively hot, it typically indicates that the filtration is overly rigorous.

When handling the motor’s bell, it’s generally recommended that you avoid applying pressure that would prevent your fingers from remaining in contact with it for an extended period. If you find yourself struggling to maintain this grip, it may indicate that your settings are overly aggressive and potentially overheating the motor.

Before commencing the tuning process, it’s crucial to ensure you have a well-defined framework in place. Conducting thorough throttle sweeps, a routine previously outlined, to ensure optimal system performance and functionality.

In PIDToolBox, load the log file and navigate to the Spectral Analyzer module. Select “Gyro Prefilt” to view the raw, unprocessed gyroscope data, or choose “Gyro” for the filtered signal, and then click the Run button to initiate analysis.

While the default filter settings in Betaflight are relatively cautious, many builds should be able to safely scale back their filtering levels from these starting points. If your quad is already noisy with default filter settings, it’s often more effective to investigate potential mechanical or electrical issues rather than simply accelerating the filtration process. Ensure that a capacitor is properly connected to the ESC to absorb energy, all screws are securely fastened, and utilize brand-new propellers.

On a clear 5-inch quad, minimal noise should occur within the frequency range of approximately 50Hz to 200Hz. This span encompasses the quad’s movements and motor vibrations. The noise in this area may stem from various sources: electrical interference possibly caused by excessive energy input to the gyro, which could be alleviated by incorporating an additional capacitor in the ESC’s energy circuit. Alternatively, it might be triggered by mechanical factors such as a loose wire compromising the gyro’s functioning. Achieving optimal filtration in this scenario proves to be a challenging task.

As guided by the creator of PIDToolbox, this device is optimally configured when the ambient noise floor sits below -30 dB at frequencies above 50 Hz. For D-term applications, optimal performance is achieved when the general noise floor remains below -10 dB. Understanding the noise levels in these specific regions could provide valuable insight into how smoothly and efficiently your drone operates. The noise level of a drone is significantly impacted by its construction quality, hardware specifications, and sometimes a loud gyroscope can be a major contributor to the overall decibel level.

If your quad exhibits noise levels exceeding this threshold (for instance, a distinct peak within the central region exceeds 0 decibels), additional filtering measures will be required. While it’s true that high-latency conditions won’t offer optimal performance, it’s essential to note that this limitation may not necessarily preclude the achievement of substantial PID advantages.

While motor noise is indeed a primary source of disturbance for FPV drone enthusiasts, the RPM filter in Betaflight is undoubtedly an essential tool for mitigating its impact, serving as the first line of defense against this type of interference. With a robust construct in place, the RPM and Dynamic Notch filters efficiently handle most processing tasks, enabling us to selectively disable numerous filters to minimize latency.

Motor noises are diverse and fascinating; let’s explore some notable examples together.

- Load the “Throttle Sweeps” log in PTB, then click on ‘and subsequently click on “”.

- Please select a text to improve in a different style as a professional editor. These are what you refer to as “warmth maps”.

Here’s a breakdown of what we’re looking at.

- The prominent horizontal stabilizer situated at the rear of the drone effectively illustrates its responsiveness to control input from the user via the sticks, accurately reflecting its real-time movements.

- The subtle energy signature of the human form is denoted by this horizontal line, which represents the harmonious resonance of the physical body. While its frequency remains constant regardless of throttle position, it exhibits its greatest intensity at the point where it intersects with the motor’s harmonic band.

- This diagonal line (3), typically the most radiant, As engine speed increases with rising throttle levels, motor noise may exhibit a corresponding rise in pitch?

- These multiples of the elemental motor noise band are. While harmonics may appear as less intense and more difficult to recognize, they typically manifest as faint signatures (4) and (5). Adjusting the dimensions as needed in situations where they are not readily apparent? While 2-blade propellers may exhibit a propensity for amplifying stronger harmonics compared to their 3-blade counterparts,

We will utilize an RPM filter to effectively mitigate these motor noise bands.

The objective is to maximize the utilization of RPM harmonics and establish an optimal “Minimum Frequency” that aligns with the starting frequency of the motor’s operating range, thereby ensuring seamless performance and efficiency. With fewer RPM harmonics, the next minimum frequency experiences significantly reduced filtering, subsequently decreasing latency.

Utilize the Knowledge Cursor Instrument, clicking on the point where the motor bandwidth starts to pinpoint the exact frequency with precision. Verify alignment within pitch-roll-yaw diagrams and identify the lowest frequency observed.

Here’s a revised version: Right away, this is an example from…

- On the left is the default RPM filter settings: three harmonics with a minimum frequency of 100 Hz.

- I refined the statement to: On precise terms, I adjusted the modification to a mere two harmonics, specifically targeting frequencies as low as 160 Hz.

By reducing harmonic distortion and increasing the cutoff frequency, you may potentially notice additional unfiltered noise from the third motor harmonics.

Although it’s relatively feeble, its potency could potentially surge in the D timeline.

Carefully examining the Dterm warmth map below, we notice that a small amount of gyro noise has unexpectedly turned into quite significant Dterm noise.

It’s generally more beneficial to employ a 3-harmonic RPM filter, rather than just one or two.

One potential issue that requires attention is the residual hum around 116Hz that remains unfiltered due to our decision to set the minimum frequency at 160Hz. To address this challenge, we need to lower the minimum frequency threshold, effectively. Submerged beneath 20Hz, an ideal resonance frequency can prevail.

Compared below are gyro signatures after filtering using three distinct settings:

- left: at least two harmonics with a minimum frequency of 160 Hz

- mid=3*harmonics*130Hz/min.freq

- Three harmonics at a minimum frequency of 100 Hz.

To eliminate motor noise, it seems we won’t need to reduce the RPM threshold after all. Under these default settings, with three harmonics and a minimum frequency of 100Hz, performance was optimal.

RPM Crossfading

As RPM filter energy varies over a range, similar to TPA, this superior characteristic gradually dissipates, typically suiting 5″ builds out of the box; however, it can be fine-tuned for larger or smaller constructions, as motor noise may shift in frequency, potentially necessitating adjustments to speed up or slow down fading according to desired sound profiles. This capability is readily available within the Command-Line Interface (CLI), exemplified by:

The revised code remains: set rpm_filter_min_hz = 100 set rpm_filter_fade_range_hz = 50

The RPM filter starts at a frequency of 100Hz with low energy levels and attains its maximum energy output by 150Hz.

Q Worth

Increasing the quality factor (Q) of a notch filter enhances its precise centration around the targeted frequency, subsequently reducing latency. Modify this within the CLI:

set rpm_filter_q = 500

While the standard settings of 500 usually suffice, it’s not uncommon to require adjustments, which can be achieved by increasing the Q value until motor noise becomes evident in the filtered gyro chart, and then adjusting back down. Don’t exceed 1000.

RPM Filtering Dimming

This feature empowers individualized control over each RPM filter to concentrate on harmonic frequencies. When using three-blade propellers, the second harmonics typically exhibit weaker performance, whereas the third harmonics tend to be more robust. To optimize signal quality, apply more stringent harmonic filtering to the third harmonic and relax the constraints for the second.

set rpm_filter_weights = [100, 0, 80]

When utilising 2-blade propellers, where second harmonics are stronger than the third harmonics, you can achieve something.

set rpm_filter_weights = 10%, 8%, 0%

You can additionally adjust lower RPM filter weights as long as motor noise doesn’t appear in the filtered gyro diagram.

The dynamic notch filter effectively eliminates unwanted sign peaks in the gyro signal, primarily stemming from bodily vibrations or hardware components such as body resonance, antenna interference, GoPro mount oscillations, and bent propeller resonance.

When the RPM filter is activated in Betaflight, it automatically adjusts the Dynamic Notch filtering algorithm to use fewer notches and a higher Q value, as the RPM filter takes on more of the load. You may adjust the Dynamic Notch filter according to your specific setup.

Analyzing the warmth map, let’s identify the number of body resonances to determine the ideal notch count. While five notches might be theoretically possible to utilize, typically one or two suffice unless the drone is severely damaged or in disrepair. When the RPM filter is activated, a single notch adjustment typically proves effective in addressing body resonance issues.

The quantization parameter (Q) directly affects the filter’s width. A better query warrants a more refined filtration mechanism, yielding fewer, yet highly relevant results and consequently reducing latency.

- What are our primary goals for this new project?

- If the default is functioning well, consider increasing it to 600, and possibly 700 as well. Keep away from exceeding 1000. If you still notice body resonance noise following filtration, reduce the Q value to eliminate any residual hum.

- Analyze the D-term heatmap to determine the impact of Q-weight adjustments on D-term noise levels and visualize any correlations or patterns that emerge.

These cutoff frequencies determine the effective operating range of the Dynamic Notch filter, delineating its optimal frequency boundaries. Enhance the harmonics by incorporating a frequency boost of approximately 20-30 Hz throughout each resonant component, yielding a richly textured and diverse sound profile.

While setting the minimum frequency excessively is crucial to ensure security, it’s also essential to note that overly rigid settings can lead to amplified resonance issues stemming from bent propellers. In the event of a crash, a wider frequency range variation is crucial to detect emerging harmonics and prevent motor overheat or damage? While we’re unclear about where resonance ultimately settles, it’s reasonable to surmise that a broader frequency range increases the likelihood of capturing it. If the Dynamic Notch fails to capture the emerging resonances triggered by an excessively low Min Frequency, your motors may overheat and potentially burn out under these circumstances?

When using quads that cannot accommodate RPM filters, such as those on tiny Whoops, consider enabling the Dynamic Notch Filter with 5 harmonics, setting Q to 350, and initializing Min Frequency at 100Hz as a starting point; then, progressively tune it by moving upwards.

During the instance setup, a singular body resonance frequency of approximately 210 Hz becomes apparent.

Despite my efforts to boost the Q to 700, I found that the setting was excessively high, as evidenced by the clearly disproportionate result. The risk of extraneous noise entering the system and being amplified within Dterm is a concern that warrants careful consideration.

Once I’ve set Q to 450, the noise is adequately mitigated. Within the underground graphs, on the left-hand side is a value of Q equal to 700, whereas the precise measurement indicates a value of Q equal to 450. You may re-examine the Dterm heatmap once again to confirm its performance is functioning satisfactorily.

Typically, start by disabling the Gyro Lowpass 1 filter, as its functionality is often redundant. Verify that the motors aren’t overheating by flying aggressively for 30 seconds and monitoring the temperature, then proceed once it appears stable.

Adjust the ‘Gyro Filter Multiplier’ slider in small increments to decrement the effect of Gyro Lowpass 2 gradually. By precisely positioning the slider, the frequency increases, thereby decreasing filtration latency and enhancing overall performance, allowing for better prop wash management and potentially even improved PID responses.

A comparison of the gyro frequency spectrum at various Gyro Lowpass filter slider values is shown, including 1.0 (brown), 1.5 (pink), and 2.0 (orange).

The three traces appear to converge, implying that the Gyro Lowpass filter’s impact on the signal is minimal and potentially excessive. As expected, the low-frequency noise remains largely unchanged even after additional filtering measures are implemented, consistent with our previous findings.

Necessary Issues:

- Prevent disabling of the Gyro Lowpass 2 filter at 2K/4K PID loop frequencies, a consequence of anti-aliasing measures in place to mitigate its effects.

- :

- Depart from Gyro Lowpass 2 with a minimum frequency of 500 Hz for optimal 2K loop performance.

- For 4K recording, the Gyro Lowpass filter can be set to a maximum of 1000Hz.

- If you’re capturing at 8K resolution, consider disabling Gyro Lowpass 2 entirely unless excessive noise becomes a concern.

The D-time period exhibits a significantly greater level of noise compared to Gyro due to its inherent delicacy, which amplifies noise as frequency increases. When dealing with D Time period filtering, exercise heightened caution and prudence subsequently.

Carefully manipulate the “D-Time Period Filter Multiplier” slider, incrementing it by one notch at a time, and observe the drone’s response during a 30-second test flight that includes aerobatic maneuvers. After landing, inspect the motor temperatures to gather data on any potential correlations. When food starts getting scorching hot, it’s generally advisable to reduce the heat by one or two notches.

Avoid overly restrictive time frame constraints in your search criteria to prevent missing relevant results. Provide sufficient clearance for feasible angled auxiliary propellers during flight operation? Inadequate DT time period filtering combined with a malfunctioning propeller can lead to overheated or damaged engines.

Here’s the direct answer:

A comparison of D-term filtering slider positions is provided, specifically showcasing settings at 1.0 (brown), 1.3 (pink), and 1.6 (orange). The heatmap indicates that reduced filtering leads to excessive noise in D-terms, unlike the low-pass filter applied to Gyro.

Here is the rewritten text:

The heatmap displays three filtered data sets in sequence from left to right: the unfiltered data, followed by the outputs of a D-term low-pass filter with cutoff frequencies of 1.0, 1.3, and 1.6 respectively.

As you reduce the D-term filtering, you may detect a thrilling oscillation in the motor’s performance. This phenomenon is likely caused by an increase in noise levels below 100 Hz. You may verify this by checking the <100Hz graphs. Considering a slower pace at 1.3 or lower, potentially even 1.2 or simply 1.1, may be a safer option.

If time period traces appear excessively noisy, a slight adjustment of 1-2 clicks on the filtering slider may provide sufficient assistance. If the D-time period hint is extremely clear, you might potentially relax filtering slightly more (unless motors are excessively hot)? Underneath the graphs, the left-hand side exhibits a pronounced and noticeable “D”-time period characteristic, whereas the precision on the right-hand side is noticeably cleaner.

Fully charged, you’ll avoid burning out your motors.

No need to enable Gyro Notch Filter and D-Time Period Notch Filter, as they’re static notch filters that have become obsolete with the advent of RPM filter and dynamic notch filters, which handle most tasks effectively.

While it’s unlikely that a static notch filter would have a direct impact on the human body, Since the dynamic notch filter typically takes care of the issue, a static notch filter is often unnecessary? You may consider incorporating a fixed notch filter to detect body resonance and subsequently reduce the dynamic notch’s frequency by one to determine which approach yields better results on your equipment.

The default yaw low-pass filter at 100 Hz cutoff exhibits a negligible latency impact and might remain unaltered. This filter proves especially useful when navigating whoops, as it effectively reduces the occurrence of yaw spin following collisions.

Using Blackbox to fine-tune a PID controller, I employ the “Basement Tuning” method through PIDToolBox for optimal performance. This DIY project is perfect for beginners and can be completed in a small space, such as a basement or bedroom, making it ideal for those with limited room to spare. The process involves conducting a series of short flights with marginally distinct PID settings, subsequently analyzing the flight logs to identify the optimal configuration.

During flight operations, rotate the quadcopter around its pitch and roll axes while maintaining stable flight control. You may learn more about the basement technique.

While the technique is commonly referred to as “basement tuning,” I’m more comfortable conducting it outdoors. I’ve experienced a few instances where I almost punched through the ceiling in frustration, creating a gaping hole with my enthusiasm. Subsequently, I always conduct these assessments in a secluded backyard or local park to ensure maximum security.

Conducting basement tuning flights necessitates exceptional aerial awareness and precise piloting skills to successfully navigate the drone within a confined indoor environment, ensuring optimal operation. Simplify your approach with these efficient tips: Do this fee profile:

With its low maximum fee, this profile significantly reduces the likelihood of losing management when transferring large amounts. Does precise and calibrated mid-stick sensitivity enable crucial input accuracy for reliable logging?

Performing checks in Angle mode may simplify the process even further than doing so in Fee mode.

In accordance with the creator’s design for PIDToolbox, Angle mode operates seamlessly alongside Fee mode; yet, it’s essential to complete the preceding step first.

- Navigate to the Setup tab and initiate calibration of the accelerometer for optimal performance.

- In the PID Profile Settings, configure the Angle mode energy to 100.

- Save your changes now?

Initially, let us mute the advantages to ensure they do not interfere with our fine-tuning process.

- Set the

- Set the

- Establish the gain, it’s set sufficiently low that it won’t introduce overshoot, yet still provides just enough phrases to assist in stabilizing the quadcopter and make it easier to manage.

Adjust the “Damping” (D: Positive Aspects) slider to initiate your evaluation from a modest value. For a standard 5-inch first-person view (FPV) drone,

What measures do you plan to take during the flight?

- Arm and hover

- Transferring the control sticks smoothly and precisely will consistently yield accurate results.

- Strike the partition walls with maximum force and precision, aiming for full-stick deflections that minimize rebounding noise.

- You can collectively transfer pitch and roll as long as you keep them under control.

- Maintain a consistent pace and endeavour to avoid prolonged moments of hovering during flight, striving for steadiness at all times.

As you incrementally increase the Damping slider value in small increments and re-fly the simulation, observe how the aircraft’s response to control inputs evolves. When elevating D becomes excessively high, your motors can produce a robust tone, making it challenging to accurately monitor the last few values – an acceptable trade-off.

To rapidly adjust a slider’s value, navigate to the Betaflight OSD menu, then select Profile and choose Simplified Tuning. Alternatively, connect via USB cable and utilize the Betaflight Configurator.

To ensure optimal performance and minimize any potential impact on flight consequences, consider swapping batteries every 2-3 flights to maintain consistent voltage levels.

Assuming a moderate usage rate, approximately 2.5MB of reminiscence is recommended for each 30-second flight, allowing for a total of roughly six flights before needing to recharge.

After completing all of the flights, download the data to your computer. To facilitate efficient log organization, I’ve designed a folder structure specifically for this purpose, available below:

I reorganize the logs by renaming them to a consistent format, such as “01_Flight_Check.log”, “d06_Slider_Worth_0.6.log”, and place them within the “Logs” folder.

Unload all logs from PTB, strip away launch and landing segments for each log.

Select the desired data then click OK. When an offset occurs within the gyro’s curves, allowing for Y correction enables a directional shift towards the top when deviating from the setpoint.

Here’s a revised version:

To optimize your Damping slider, simply identify the best balance for your desired sound quality, where one setting stands out as the most effective choice. The ideal response should resemble the novice’s line in the graph, characterized by minimal to no overshooting. Having a small degree of overshooting is acceptable.

When examining your traces, if they exhibit irregularities with numerous peaks and troughs, this phenomenon is known as oscillation, suggesting that the signal may be excessively turbulent or your interventions are insufficient in magnitude.

The graphs on the precise data are also extremely valuable.

- Is the maximum overshoot magnitude ideally closer to unity, with a value as near to one as possible?

- Is the time it takes for a system to reach its target setpoint ideally decreasing as the setpoint increases?

When acquisition gain is low, you’re likely to experience overshoot and potentially oscillate. As demand increases, there is likely to be significantly reduced overshooting, which will in turn lower the risk. Conversely, this development will lead to a corresponding rise. When the gain D is excessively high, undershooting can occur, resulting in a preliminary peak that fails to reach the setpoint, rendering it suboptimal. Discover a response that exhibits optimal performance with minimal overshoot and remarkably high precision.

Zooming in or selecting fewer logs allows you to view the data with greater clarity. Let’s focus on the Roll and Pitch axes alone.

While initially assuming a perfect value of 3, further clarification on the pitch and roll’s significance in this context would be beneficial to ensure accuracy. Perhaps refining the initial assertion with more precise language, such as: It appears that the ideal worth for each pitch and roll is indeed orange, or possibly 1.0?

The phenomenon of distinct pitch and roll stability in PD systems is commonly observed due to significantly varying weight distributions. To fine-tune your aircraft’s response, adjust the Damping slider to achieve the desired pitch, record the resulting Pitch D value, and then move the Damping slider to the optimal roll setting, subsequently calibrating the Pitch Damping slider to mirror the previously recorded Pitch D value.

It’s generally recommended to adopt a slightly more cautious approach, thereby avoiding the potential pitfalls of over-allocating funds to D. When uncertain, consistently opt for a lower P and higher I to drive overall PID performance improvements by the end, as D typically becomes the rate-limiting factor in such scenarios.

What’s become apparent is that the step response device exhibits a certain fragility, its P/D stability potentially dropping below my desired threshold. After uncovering a perfectly valuable discovery, I typically increase P/D stability by 5-10%. That’s entirely your personal preference, and I’m free to try an alternative if that’s what you’d prefer.

The size of a drone significantly affects its power-to-drag (P:D) ratio, with larger drones typically exhibiting higher P:D ratios. A 5-inch drone may utilize a damping slider with settings ranging from 0.8 to 1.1, whereas a miniature whoop might employ settings between 1.4 and 1.6.

Verify that the identical settings are applied to the Grasp Multiplier slider by adjusting it in 0.2 increments? To establish standards for a 5-inch drone, set initial values at 0.8, 1.0, 1.2, 1.4, 1.6, and 1.8, respectively.

Please exercise caution while approaching the quad during this period to avoid any potential hazards. When downshift acquisition is too aggressive, the car’s speed may surge upwards unexpectedly. Pay close attention to motor noise and stop immediately upon detecting any unusual or alarming vibrations.

One might notice that the shapes of the step responses exhibit minimal variation despite diverse value inputs, with peak values remaining relatively consistent. The response curve’s principal shape is determined by the P/D ratio. While amplifying positive attributes will have little impact on response format, increasing P/D positive attributes can actually mitigate latency.

When you’ve achieved the optimal Grasp Multiplier increase, a milestone is triggered by any of the following occurrences:

- In the unlikely event that you detect a thrilling oscillation, further purchases are no longer feasible.

- If latency continues to remain unaltered or exhibits minimal reduction, it is likely that you have reached a plateau in your optimization efforts, signifying the attainment of an optimal tuning window. The motors are operating at maximum capacity, yet failing to yield any additional operational efficiency.

The maximum performance attainable is contingent upon the level of noise within your system and the amount of filtering employed. Increased permission for PID processing yields numerous benefits. Initially, it’s advisable to adjust the Grasp Multiplier slider downwards by one or two notches once you’ve found the optimal value. Avoid imposing excessive limitations on propellers to accommodate possible irregularities?

Drones equipped with advanced cell-based batteries featuring higher voltages tend to necessitate reduced D-plus values. On a 6-series quadcopter, positive voltage readings for D can typically range from the mid-to-high twenties to low thirties, while a 4S setup tends to register values in the mid-to-upper forties.

For my specific setup, a value of 1.6 seems to offer the lowest latency, with minimal improvement when increasing to 1.8.

If you fail to detect captivating oscillations, employ the Spectral Analyzer to graphically depict D-term values. With advancements in performance, the motors have the potential to emit a thrilling resonance, predominantly within the frequency range of 40-80Hz, which is especially pronounced during acceleration. When variability in noise on this frequency escalates as positive aspects grow, a characteristic signature of PID-related oscillations begins to emerge.

Clearly evident are peaks around 60Hz for olive at 1.4, inexperienced at 1.6, and cyan at 1.8 frequencies. While version 1.6 shows a notable latency enhancement, I would not take the risk and would likely opt for versions 1.4 or even 1.3 to ensure a safer choice.

The debate persists as to which approach yields a superior outcome: incorporating additional D-term filtering mechanisms alongside enhanced D acquisition capabilities, or conversely, implementing reduced D-term filtering and decreasing D acquisition. However, refrain from reducing the D-term filtering threshold excessively, as this may lead to catastrophic consequences if you encounter an obstacle or deform a component. Based on the input provided, I would revise the text to:

From a position of authority, I’m telling you it’s no laughing matter.

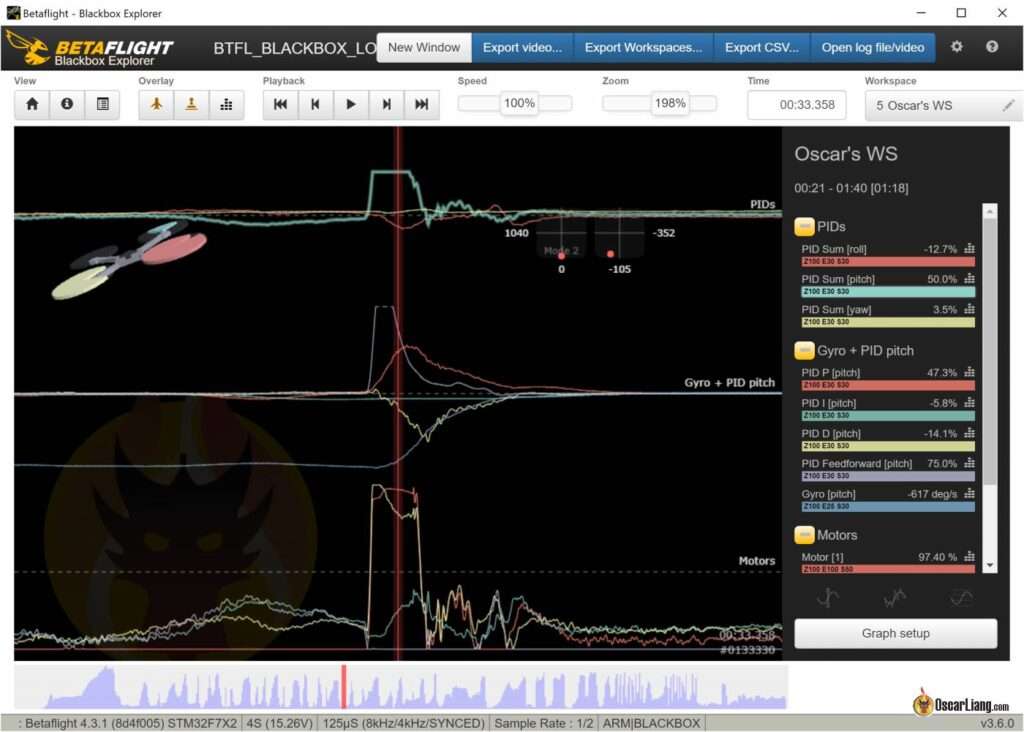

Upon identifying the ideal D gain, analyze the setpoint tracking performance by graphing the gyroscopic data alongside the setpoint values. The traces should roughly parallel each other, suggesting that the quad is accelerating and decelerating at a consistent rate matching the setpoint. Despite this, a significant gap might still exist, signifying latency. During the next phase, we will narrow down this gap by leveraging Feedforward techniques.

When engaged, Feed Ahead (FF) technology amplifies the response of your drone’s quadrature motors, ensuring rapid and precise movement as soon as you manipulate the control sticks, thereby achieving a more accurate and immediate alignment with the desired trajectory. Unlike the P-time period, which is triggered solely by a PID error, Feed Ahead gauges the velocity of stick deflection. The rapid motor transfer occurs when the stick strikes, significantly outpacing traditional P-time protocols.

Feeding ahead enables quads to respond swiftly to input, providing an enhanced experience with faster and more controlled flight capabilities. This smooth control is beneficial for all types of flight, including cinematic flights, as it minimizes the delay between pilot input and quadcopter reaction.

While tuning the Feed Ahead, I aim to perform a series of snap rolls and flips to scrutinize the Gyro/Setpoint charts thoroughly. To accurately determine the maximum thrust of your drone’s motors, it is essential to configure the flight controller using a predefined or custom-made fee profile that reflects the actual motor characteristics. One way to do this is by temporarily switching to an unused fee profile in Betaflight and then performing a max fee test at full stick deflection. This approach helps ensure that the thrust values recorded during the test are as accurate as possible, considering the unique properties of your specific motors. Examine your account to determine the validity of these charges.

Employing the bidirectional encoder (BE) as a substitute for the traditional step response device in a physical training box (PTB), analyze the setpoint and gyro signals. The gyroscope should monitor its setpoint closely and respond with minimal latency. The gyro should ideally operate precisely above the target setpoint.

If Feed Forward overshoots (the gyro strikes earlier than the setpoint), then the FF is simply too excessive. Here’s a revised version: The demonstration suggests that 0.5 is insufficiently low, while 1.0 is still not sufficiently high; however, 1.5 proves to be marginally too much, overshooting the mark. While some individuals may benefit from a feedforward approach, in the current context, I would recommend considering alternative methods to achieve the desired outcome.

If the foreign direct investment is excessively large, it might prompt a policy response from the host country’s authorities, potentially leading them to adopt measures aimed at countering its effects.

Regardless of your preferred flying style, feedback can be beneficial and isn’t limited to specific types of flight. Although even cinematic flying can benefit from an adequate amount of feedforward, it’s crucial to note that when transferring the stick smoothly and gradually, this gain doesn’t necessarily trigger. FF will promptly reduce latency by minimizing the time gap between stick input and quad response. For a more stable and effortless flying experience, consider enabling Expo mode, increasing the radio control’s (RC) smoothing feature, or reducing your aircraft’s sensitivity.

The non-compulsory setting for feedforward gain increase is often referred to as FF+ or Gain Boost. The issue is that the gyroscope’s initial response lags behind its target setpoint, but then adjusts and converges to the desired position over time? While initial overshoot is common when scaling up a gyroscope, it’s crucial to adjust accordingly to prevent divergence over time, ensuring the system stays within the desired range.

What we gain ultimately relies heavily on intuition. The key is not to overcomplicate things: you merely need enough pitch (P) and depth (D) control to stabilize the drone’s flight, without being overly reliant on precise adjustments. When flying steadily at a low altitude and requiring minimal manual control, your drone is designed to hold its position for an extended period. When detecting drift, it’s essential to secure the subsequent acquisition promptly.

In Betaflight, the I-term tuning window is remarkably broad, especially for high-performance 5-inch quads. Typically, a setting of 0.5 to 1.5 on the I-time period slider proves effective for five-inch quadcopters. This expansive canvas allows us to adjust everything else initially, then refine the outcome in due course. With optimal I acquisition settings, your quad will experience enhanced precision, yet if the I acquisition is overly aggressive, it may lead to sluggish oscillations that should be mitigated.

The step response device in the precision torsion balance (PTB) appears inefficient for determining the I-time period due to its consistent step response for both pitch and roll, regardless of the I-acquire slider value (i.e., 0.4 to 2.0). Notwithstanding its limitations, this setting is still worth utilizing to fine-tune yaw performance, as I have found that a typical starting point is around 1 on the slider for standard 5-inch quadcopters.

Can you hear the pitch of the engines as they rev up? To optimize your game’s sensitivity, aim to set the ‘I acquire’ slider at its highest point, gradually increasing it until you notice slow rebounding and oscillations during rapid movements, before adjusting downward by one or two notches. While it may prove challenging to enlist the assistance of our quads in identifying bouncebacks, this is largely attributed to features such as “I-term relaxation” available in Betaflight. In recent times, it’s essential to leverage unusually high levels of returns without incurring significant negative impact.

For my typical five-quadrant setup, I usually leave the acquisition slider set to 1.

As you gain confidence with your i-term, feel free to adjust the cutoff according to the drone’s response time and agility. While freestyle drones often function optimally with default settings, some adjustments might be necessary for specific flying styles or environmental conditions. What are the key considerations for building a top-notch racing drone?

Firstly, **stability** is crucial – the drone must maintain its aerodynamic shape while flying at high speeds. This demands a well-designed airframe and a reliable stabilization system.

Next, **agility** is essential – the drone should be able to quickly change direction, accelerate or decelerate, without losing control. A powerful motor and lightweight propellers are necessary for this.

Speed is also vital – racing drones need to reach high velocities, typically exceeding 60 mph (97 km/h). A high-quality ESC (Electronic Speed Controller) and a suitable motor combination are critical here.

Other crucial components include **optical sensors** for detecting obstacles, a reliable **flight controller**, a robust **frame design**, and high-performance **propellers**.

Additionally, the drone’s **weight** should be carefully managed to achieve optimal speed and agility. To optimize image quality for larger drones equipped with high-end cameras, such as those used in cinematography or long-range surveillance, consider setting the ISO cutoff at 10.

While Dynamic Damping significantly boosts the pitch’s responsiveness during aggressive maneuvers, its impact is negligible during normal cruising conditions. Utilizing this technique effectively contributes to reducing engine heat buildup.

I utilize dynamic damping techniques in my projects to achieve desired levels of motion control.

- Check your current Mahindra D-Max valuation? As the Dynamic Damping slider is currently set to 0, this should be identical to Byproduct.

- Increase the Dynamic Damping slider to 1 initially.

- Scale down the Damping slider to maintain the original D Max value, thereby reducing the baseline D acquisition used during normal flights to keep your motors at a comfortable temperature.

To simplify issue management, consider setting the Dynamic Damping slider to 0 and leaving the Damping slider untouched; this approach allows the quad to utilise a consistent D value throughout its flight, with any adjustments up to you.

The Anti-Gravity technology’s beneficial outcomes help mitigate the effects of wobbling and nose-dive incidents when releasing the throttle following a punch-out maneuver. In order to counterbalance the unwanted fluctuations, AG momentarily increases the acquisition pace through a series of controlled throttle pulses. While an excessively high AG acquisition rate may not be detrimental to overall system performance, it can still cause your quadcopter’s motors to stutter or oscillate rapidly when you suddenly increase throttle input due to the amplified effects on both Proportional (P) and Integral (I) components.

When adjusting throttle quickly, consider scaling back the default setting to prevent potential wobbling issues. I found that for five freestyle drones, an ideal range is 8 to 12.

Would you like to experience the thrill of anti-gravity? Simply adjust your AG settings while wearing goggles or inspect Blackbox logs for nasal dip indicators – witness the profound effects of gravity defiance firsthand.

Dynamic Idle

Improves stability, optimizes propwash management, and minimizes the risk of ESC (Electronic Stability Control) desynchronization. This feature enhances motor acceleration from idle, thereby refining control and quickness at the lower end of the throttle range. The refined features encompass enhanced flip and roll stoppers, offering increased responsiveness at low throttle settings and more effective braking capabilities.

Upon Dynamic Idle being enabled, the percentage-based Static Motor Idle setting in the Motors tab is automatically disabled.

To set up Dynamic Idle, you must first ensure that your vehicle’s engine is warm and the transmission is in park. Then, locate the idle control module (ICM) on the driver’s side of the dashboard. Press the ICM to access the menu options. Scroll through the menus until you find “Dynamic Idle” and select it. The system will prompt you to confirm that you want to enable Dynamic Idle. Once confirmed, the system will automatically adjust the engine idle speed to the optimal setting for your vehicle’s specific conditions.

- Bi-directional DShot capabilities are now available within the Motor tab. If you’ve previously enabled RPM filtering, you’re ready to go.

- Establish a suitable idle RPM range within the PID Tuning webpage, typically ranging from 20 to 40 for smaller aerial platforms like five-inch drones.

The idle RPM sweet spot is typically established through careful consideration of propeller measurements and pitch settings. Typically, smaller propellers with decreased pitches demand higher rotational speeds. Worth adjusted upward in windy conditions to offset potential instability.

| Prop Sizes | Excessive Pitch Props | Low Pitch Props |

| 31mm/1.2″ | 84 | 167 |

| 40mm/1.6″ | 62 | 124 |

| 2″ | 50 | 100 |

| 2.5″ | 40 | 80 |

| 3″ | 33 | 66 |

| 3.5″ | 28 | 57 |

| 4″ | 25 | 50 |

| 5″ | 20 | 40 |

| 6″ | 16 | 33 |

| 7″ | 14 | 28 |

| 8″ | 12 | 25 |

| 10″ | 10 | 20 |

:

- Reduces hold time when inverted (motors produce more thrust downwards). This incremental improvement will enable the quad to stabilise almost perfectly at zero throttle, thereby significantly enhancing throttle control and overall flying experience.

- : Dangers low throttle instability.

:

- : Default is normally 5.5%. Carefully inspect your motor within the motor tab, utilizing a smoke stopper or a bench power supply to limit current flow.

- Spin the motor on the ESC’s idle watt setting (for example, 5.5% at around 1,055) while keeping an eye on the reported RPM; this operation requires bidirectional DShot functionality.

- The ideal dynamic idle value can be calculated by dividing the RPM worth by 100, providing a precise benchmark for optimal performance.

By pressing the throttle stick swiftly upwards, Throttle Increase instantly boosts your throttle value, granting a temporary power surge. While this setup might enhance throttle responses with added dynamism, it simultaneously increases the risk of unpredictability.

- The default value of five usually operates effectively.

- Adjustment Ideas:

- If you find the throttle difficult to manage, consider reducing its value.

- Some enthusiasts go as far as disabling Throttle Increase altogether, setting it to zero to ensure the most consistent and predictable throttle response possible.

- Explore a diverse range of styles to discover which one yields the most impressive results on your airborne apparel.

As the battery reaches its maximum capacity, this feature minimizes the maximum motor drive potential; however, as the battery’s voltage decreases, it increases the motor drive value accordingly. The aircraft’s aerodynamic design ensures consistent flight performance throughout its journey. Be cautious not to compromise your judgment on when to land due to the similarity in feel between the quad and the entire pack.

- Allow for thrust linearization at a maximum of 20% deviation.

- :

- Tunes PID parameters to optimize responsiveness and management when operating at low throttle settings.

- Reduces the Proportional-Integral-Derivative (PID) controller’s sensitivity when excessive throttle is detected, effectively damping out oscillations similarly to how TPA (Throttle Positioning Algorithm) operates.

- This product specializes in reducing nose dips, offering significant benefits to pilots of whoops and drones that employ 48KHz pulse-width modulation (PWM) frequencies with their electronic speed controllers (ESCs).

Because boosting PID at low throttle increases motor temperature, consider adjusting the grip multiplier to prevent overheating.

The Throttle Position Amplifier (TPA) stands for Throttle PID Attenuation.

To effectively tune transducer pressure amplifier (TPA), perform a throttle sweep and analyze the frequency response versus throttle heatmap. When engine oscillations occur at a specific throttle level, Total Pressure Augmentation (TPA) is employed to mitigate this issue.

In the latest Betaflight iteration, the system primarily reduces D-acquisition levels when the throttle exceeds a specific threshold, thereby mitigating oscillations. In older versions of Betaflight, the TPA mode attenuates both P and D filters simultaneously. To re-enable this feature, enter the following command in the CLI: `set tpa_mode=PD`.

I typically strive to set the throttle value in TPA as high as possible, which enables D-acquire to remain more consistent across a broader throttle range. Ensure the throttle setting is slightly below the point where D-time oscillations start to manifest. If oscillation commences around 1800 throttle, I would potentially implement the following adjustments: TPA = 0.75, throttle at 1750.

These options are often undesirable for FPV freestyle drones but prove particularly useful for line-of-sight pilots.

However, Yaw typically doesn’t require much tuning, as its default acquisition settings usually work effectively. The tuning window for yaw exhibits a considerable range. In contrast to pitch and roll, which rely heavily on thrust generated by propellers, yaw hinges on the inertia produced by propeller rotation. As a direct result, the inherent slowness of yaw will prevent it from overshooting its setpoint, thereby rendering unnecessary any tuning of yaw PID parameters.

While yaw rates may be insufficiently rapid for dynamic phrases to exert notable influence, it is generally unnecessary. While considering the option, it’s crucial to weigh potential benefits against possible drawbacks, such as increased vibrations that could arise. The nuances of Yaw’s linguistic landscape are still discernible in the remnant phrases.

Tuning yaw using a step-response evaluation is possible, just as we previously did for pitch and roll. If slow oscillations appear towards the end of the graph, the time interval is likely too long. If rapid oscillations occur, then the P-Time period is likely far too lengthy.

When performing a throttle pump, you likely experience yaw shakes; to mitigate this, consider isolating yaw control from the slider tuning and setting the Yaw PID independently. Selecting the PID tuning tab and opting for ‘RP’ in the ‘Slider Mode’ dropdown list replaces ‘RYP’, allowing a more precise control. This exclusion of yaw values from the sliders ensures that you can input PID numbers specifically for yaw control. To hone five different freestyle and cinematic building skills, attempting 100 of each prototype may be an excellent starting point. As yaw tends to exhibit sluggish reaction times, attempting higher values may prove effective.

How good is sweet sufficient? While investing time in optimizing filters and PID numbers can yield improvements, this process is often situation-specific, and the relationship between effort and outcome may not always be directly proportional. I typically stop once something seems satisfactory and let it stand until a specific issue arises that needs resolution.

A 5-inch FPV drone should effortlessly take flight with standard Betaflight settings. When your quad exhibits vibrations, they may stem from mechanical or electrical issues, or potentially a faulty gyro on the flight controller. How to Diagnose a Faulty Gyro?

- While one axis exhibits significantly higher noise levels compared to the others, this aberration is most pronounced in the low-frequency range below 200Hz.

- Rotate the football field by 90 degrees. If the noisy axis aligns with the direction of rotation, the gyroscopic sensor may potentially be faulty.

The pitch axis exhibits significantly more noise than roll and yaw, characterized by intermittent bursts of high-frequency noise stemming from the gyroscope’s inherent imperfections? Potential causes:

- Excessive energy wires proximal to the gyro?

- Provision of noisy energy to the Football Club.

- Poor board design.

:

- Removing all unnecessary proximity wiring adjacent to the gyroscope.

- You may attempt .

- Consider adding a small bypass capacitor (220uF-470uF) between the VBAT/VCC pad and the ground plane to filter out noise and improve the stability of the voltage supply.

- If none of these alternatives appeal to you, then consider reconfiguring the FC entirely.

To achieve a stable flight experience with Betaflight, RC smoothing plays a vital role in mitigating the effects of feedforward at critical points. The correct RC smoothing settings hinge on your RC hyperlink configuration. To ensure accurate results, it’s recommended that you select the correct RC_Link preset upfront to prevent potential issues.

The Auto issue is arguably the most crucial setting, as decreasing it yields a more responsive and twitchy feel, while increasing it produces a softer and smoother ride at the cost of reduced responsiveness. Here is the improved text in a different style as a professional editor:

The guiding principle I adhere to is straightforward and uncomplicated.

- : Racing

- What’s your default worth? It’s pretty cool for freestyle.

- : Cinematic

- Effortless sailing potential with slight potential for delays noticeable by a few.

- Can we achieve highest possible smoothness without compromising on performance?

Dangerous gear and pilots require increased receiver compensation (RC smoothing) to ensure reliable communication between the transmitter and receiver, thereby minimizing signal degradation and maintaining stable flight performance. Lack of high-quality radio management equipment, outdated and poorly maintained gimbals, and novice pilots prone to erratic handling are just a few of the issues that can hinder optimal performance. Factors contributing to jerkiness in RC instructions?

Carefully review black box logs to verify the presence of readily accessible setpoints; should the setpoint prove non-intuitive (exhibiting step-like behavior following RC instructions), simply fine-tune the smoothing algorithm.

It’s likely you’re experiencing noise in your setpoint that peaks at specific harmonics of the power line frequency (50Hz, 150Hz, 250Hz, or 500Hz), which may be indicative of a problem with the RC smoothing algorithm. Frequencies are ubiquitous packet charges within radio control hyperlinks? The monitor for gamers: On this occasion, it’s Crossfire 150Hz.

If insufficient filtering is applied to RC instructions, the RC signal might not be sufficiently smoothed, potentially generating noise on the radio hyperlink packet frequency.

RC (Rate-Capacity) smoothing eliminates abrupt changes and stabilizes the set-point, significantly reducing the perceived jerkiness of P-time period control. Notwithstanding its additional provision of delay to both feedforward and setpoint, your quadcopter may experience slightly reduced responsiveness. While RC smoothing can be beneficial, applying an excessive amount of smoothing can undermine the very purpose of achieving rapid RC packet transmission, as offered by ExpressLRS, thereby compromising performance and responsiveness.

The goal is to streamline processes without introducing unnecessary delays. To achieve a smoother RC experience, consider adding extra exposure, which can have a similar effect without incurring the latency penalty.

To achieve optimal results, start by selecting the appropriate RC Hyperlink preset and loading it accordingly. If you failed to apply the correct RC_Link preset to your specific RC link and packet frequency, it may lead to difficulties with Feedforward functionality. Feedback instability occurs due to the absence of stepping smoothing in remote control (RC) instructions.

If the PID_Sum exceeds its default threshold of 500, restricting it by 50%, consider increasing this limit to 1000 if PID settings remain excessively high. To accomplish this task, issue the following command in your terminal: set pid_sum_limit=1000. Although it may not always make a distinction in flight behavior as motors might potentially saturate at this rate anyway?

When experiencing random vibrations and wobbles stemming from feedforward jitters that persist despite using the correct RC Hyperlink preset or increasing RC smoothing, it’s possible that the issue is attributable to the ADC filter.

Ensure that the Automatic Dynamic Compass (ADC) filter is disabled within your radio’s system settings under the “Hardware” tab.

When the ADC filter is enabled, anomalous feedforward spikes appear in the Blackbox logs, leading to detrimental oscillations and vibrations that compromise system stability.

Edit Historical past

- Nov 2022 – Information created

- As of June 2024, all content has been updated to accommodate the latest advancements in Betaflight 4.5.