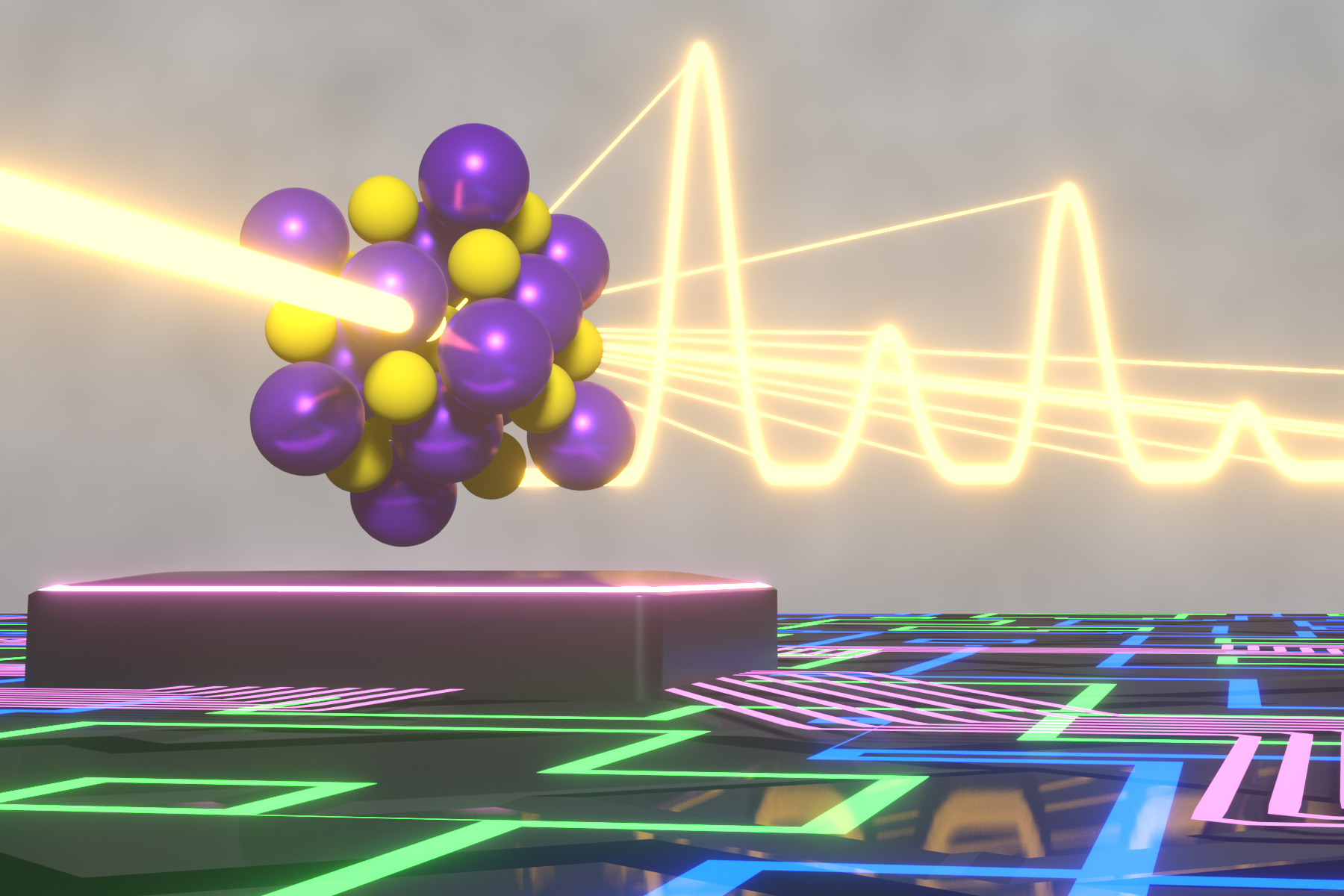

Since more than a century ago, researchers have leveraged X-ray crystallography to uncover the intricate structures of crystalline materials, including metals, rocks, and ceramics.

Despite being most effective when applied to an intact crystal, numerous scientific studies actually work with powdered forms containing fragmented remains of the crystal. This complicates the task of assembling a cohesive overall structure.

Researchers at MIT have developed a cutting-edge generative artificial intelligence model capable of significantly simplifying the process of determining the structures of powdered crystals. The prediction model could help researchers characterise materials for use in batteries, magnets, and numerous other applications?

Before considering any materials, understanding the construction process is paramount. What’s crucial for superconductivity, fundamental to magnets, and essential for grasping the photovoltaics you’ve developed is a profound comprehension of this phenomenon. According to Danna Freedman, the Frederick George Keyes Professor of Chemistry at MIT, “The ability to manage materials effectively is crucial for any utility, be it a physical infrastructure or an intangible resource.”

Freedman and Jure Leskovec, a professor of computer science at Stanford University, are the senior authors of the newly published research, which Eric Riesel, a scholar with a background from MIT, and Tsach Mackey, an undergraduate from Yale College, serve as the primary writers of this study.

Crystalline structures, comprising metals and various inorganic substances, arise from intricate lattices featuring numerous identical, repeating molecules. Molecules that exhibit specific structures and dimensions, comprising precisely arranged atoms.

As X-rays interact with these complex lattices, the atomic structures scatter the radiation with distinct angles and levels of intensity, providing valuable insights into the precise arrangements of the atoms and their chemical bonds. Since the early 20th century, researchers have employed this method to study supplies, in conjunction with organic molecules exhibiting crystalline structures akin to DNA and certain proteins.

When attempting to repair powdery crystals, the process becomes significantly more challenging due to the lack of three-dimensional structure in the fragmented state.

The exact lattice structure still prevails, arising from the aggregation of microcrystals that collectively define a powder’s composition. Though the lattices might appear identical to those of a large crystal, they are fundamentally distinct due to their entirely randomized orientation, notes Freedman.

For thousands of these complex materials, X-ray diffraction patterns remain unsolved, awaiting deciphering. To tackle the constructions of these supplies, Freedman and her team trained a machine-learning model on data from the Materials Project database, which houses over 150,000 materials. Researchers initially pumped hundreds of thousands of simulated supplies into a cutting-edge mannequin capable of mimicking X-ray diffraction patterns in real-time. Utilizing these patterns, researchers trained their artificial intelligence model, dubbed Crystalyze, to predict structures solely by analyzing X-ray patterns.

The mannequin dismantles the method of predicting constructions into several distinct subtasks. The process begins by defining the lattice’s structural parameters – its dimensions and morphology – as well as identifying which atomic constituents will be incorporated within this framework. The programme then accurately forecasts the interactions among atomic entities within the designated area. For each diffractive sample, the model produces numerous hypothetical structures, which can then be evaluated by inputting these structures into a separate model that calculates corresponding diffraction patterns for each structure.

“Our cutting-edge mannequin is a generative AI, capable of producing novel outputs it has not encountered before. This unique capability enables us to generate multiple distinct predictions.” After careful analysis and refinement, the revised text reads:

“We’re capable of making 100 predictions, following which we can accurately forecast what the powder sample should resemble based on our predictions.” Once the input matches exactly what you see as the output, then we can confidently say we got it right.

Researchers analyzed numerous thousands of simulated diffraction patterns generated by the Supplies Venture using a mannequin. Additionally, they thoroughly scrutinized the mineral’s composition using more than 100 experimental diffraction patterns from the RRUFF database, containing over 14,000 pure crystalline minerals, with the remaining portion serving as a holdout set for their training data. According to the available data, the mannequin was accurate in approximately 67 percent of cases. They began exploring the mannequin’s capabilities by applying it to previously unsolved diffraction patterns. The knowledge derived from the Powder Diffraction File, containing over 400,000 datasets of both solved and unsolved substances, provides a comprehensive repository of diffraction data.

Researchers leveraged their custom-built mannequins to develop constructions for over 100 previously unsolved patterns. Moreover, Freedman’s team leveraged a custom-made mannequin to devise novel combinations for three chemical substances developed in their laboratory by exploiting the fact that certain components fail to react under normal pressure, yet form compounds when subjected to high-pressure conditions. This strategy enables the creation of novel materials boasting distinct crystal structures and physical attributes, despite sharing a comparable chemical makeup.

Graphite, a soft, slippery substance, and diamond, the hardest natural material known, are two remarkable forms of pure carbon, offering contrasting properties that highlight its versatility in manufacturing various supplies. The materials Freedman has developed, comprising bismuth and a distinct element, hold significant potential in designing novel materials for perpetual magnets.

Researchers uncover significant breakthroughs in understanding complex mixtures, successfully deciphering three previously unknown constructions and discovering numerous new supplies informed by current scientific knowledge.

The potential to design constructions of powdered crystalline materials could significantly benefit researchers across a wide range of materials-related fields, according to the Massachusetts Institute of Technology (MIT) team, which has developed an online platform to facilitate access to its model at [insert URL].

The research was supported by a grant from the United States government. The Division of Vitality and the National Science Foundation.