Artificial Intelligence-Enhanced Drone Technologies Revolutionize Bridge Safety and Reduce Maintenance Costs

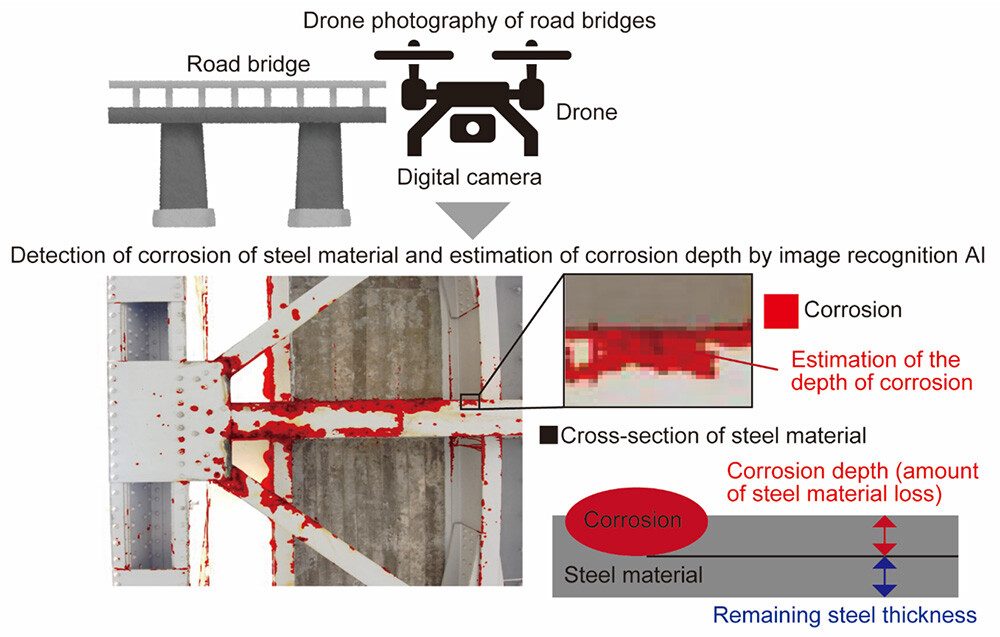

Developing a pioneering approach to identify and revitalize corroded metal components on bridges through the fusion of AI-powered image processing and unmanned aerial vehicles (UAVs). This innovative approach aims to overcome the limitations of traditional visual assessments, ensuring the integrity and extended lifespan of metal structures globally. Utilizing this cutting-edge technology, businesses aim to substantially reduce costs and energy consumption in maintaining critical infrastructure such as bridges.

Detecting corrosion before it becomes a major issue requires innovative and effective strategies. One such approach is utilizing advanced non-destructive testing (NDT) techniques to identify early warning signs of corrosion. By leveraging cutting-edge technologies, such as acoustic emission testing or electromagnetic testing, engineers can pinpoint areas where corrosion may be occurring, enabling prompt maintenance and minimizing the risk of costly repairs?

Corrosion in metal components, particularly those situated in inaccessible locations, poses a crucial challenge to the maintenance of bridges. Conventional inspection methods often rely on visual examination, posing significant challenges in accurately evaluating the extent of corrosion penetration. As NTT clarifies, the system may simultaneously identify corrosion and measure its depth through drone imaging and AI-powered inspections, a task previously challenging to accomplish via visual assessments by human inspectors. By leveraging automation and drones combined with AI technology, inspectors can effortlessly detect damage and estimate corrosion depth without requiring costly scaffolding or ultrasonic probes.

The Federal Highway Administration has underscored the challenges of detecting corrosion, citing inconsistencies in test results due to varying levels of operator expertise and tool sensitivity. To address these challenges, NTT has integrated AI technology into its drone-based imaging methods, enabling precise detection and quantification of corrosion in metal bridge structures. This convergence of advanced technologies has the potential to significantly boost the efficiency and precision of bridge inspections, ultimately ensuring the long-term structural soundness of aging infrastructure.

Actual-World Utility in Japan

Japanese telecommunications company NTT and its subsidiary NTT e-Drone Tech successfully tested an innovative AI-powered drone solution to inspect a bridge in Kumagaya City, demonstrating the potential of this technology for infrastructure assessment. The drones’ photographic captures were subsequently scrutinized by an artificial intelligence system, which pinpointed areas of corrosion and estimated the extent of damage. By leveraging NTT’s expertise, this innovative technology holds the promise of significantly reducing inspection costs while simultaneously enhancing the accuracy of corrosion detection.

“According to a recent press release from NTT, the company has achieved enhanced labor efficiency and reduced maintenance costs by leveraging an ultrasonic device to measure loss quantity in metal cross-sections of corroded areas utilizing drone imaging and AI-based inspection.” NTT aims to simplify and reduce costs for infrastructure managers by automating maintenance of bridges and other metal structures.

Future Outlook and Growth

NTT aims to expand the application of this technology beyond traditional bridge structures to encompass various other infrastructure types, including metal towers and guardrails. NTT aims to launch its AI-based inspection technology as a tool for enhancing the efficiency of drone operations by refining the accuracy of the system by fiscal year 2025.

NTT aims to foster a more sustainable future by mitigating the increasing costs of infrastructure maintenance and ensuring the safety of critical infrastructure assets. The corporation plans to assess the feasibility of its technology by evaluating the outcomes of its demonstration project in Kumagaya City, with the goal of identifying ways to apply this expertise to a wider range of infrastructure facilities.

Learn extra:

As Editor-in-Chief of DRONELIFE and CEO of JobForDrones, Miriam McNabb is a respected authority on the rapidly evolving drone industry, with a keen eye on market trends and regulatory developments. As a renowned expert in the field of business drones, Miriam has authored more than 3,000 articles focused on the industry, solidifying her reputation as a prominent figure globally. Miriam holds a degree from the University of Chicago and boasts more than 20 years of experience in high-tech sales and marketing, specializing in pioneering technologies.

For specialized drone trade consulting or compelling writing services,

TWITTER:

Subscribe to DroneLife .