Wie Sie Kosten senken und die Vorteile der Automationsklassiker Decide & Place, Prüfen und Dosieren am besten für sich nutzen

Author: As Business Unit Manager for Low Value Automation at igus GmbH

Automate tedious tasks such as picking, dosing, milling, or inspecting – there are numerous monotonous, repetitive, and exhausting jobs that simply beg to be streamlined. Acquiring a robot alone ultimately leads to no solution. At the end, the entire system comprising robots and components such as intelligent systems, grippers, and sensors must function seamlessly together. Especially small and medium-sized enterprises (SMEs) often struggle to find the right solution, unsure where to look or what it should even look like. It’s equally important to start simply. The automation expert helps willing-to-automate individuals find the simplest and most cost-effective solution that actually works.

What sets Das Besondere apart is that interested individuals don’t just find robots and individual components on the marketplace, but also gain insight into how others operate. As a readily available source of inspiration for immediate replication, online offers over 400 instantly adaptable automation projects from real-world practice. From automated worm farms to a Berlin picker and on to agricultural robots that detect and destroy weeds. Thousands of companies worldwide have successfully implemented automation solutions on RBTX.com without requiring prior knowledge of construction techniques. Ninety-five percent of these all-encompassing solutions are available for under €12,000. Low-value solutions consistently demonstrate a payback period of just 3-12 months. Zu den Hauptanwendungsbereichen zählen unter anderem Decide & Place-Aufgaben, die Qualitätsprüfung sowie Klebe- und Dosieranwendungen.

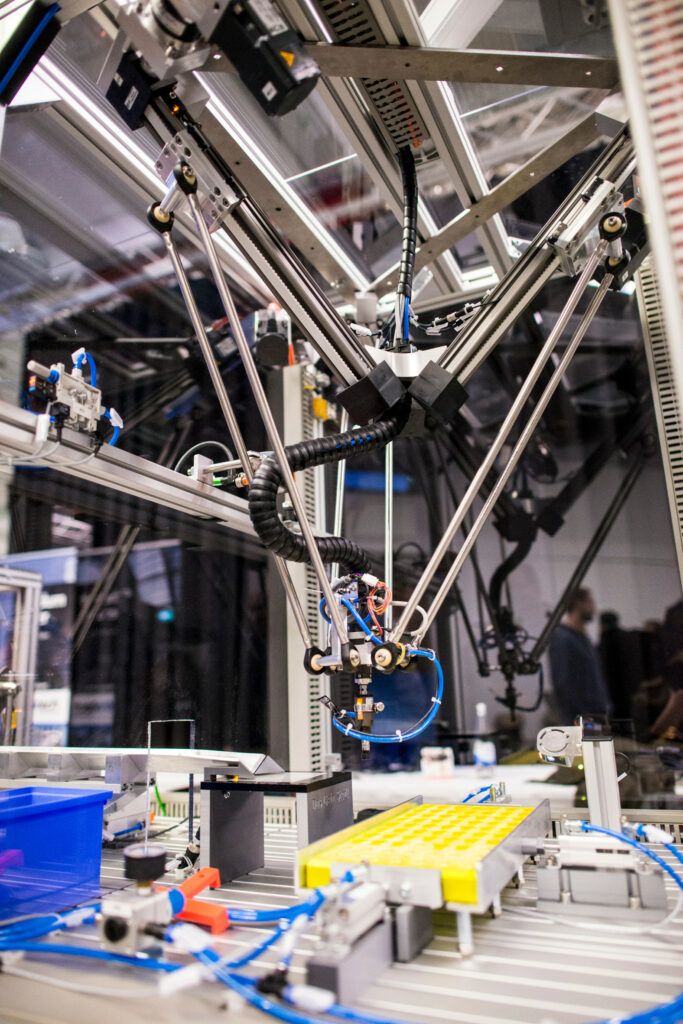

Ein Decide & Place-Roboter befördert ein Objekt zuverlässig von A nach B. Often, these repetitive and time-consuming tasks present a significant opportunity for optimization within a production process. During machine assembly, palletizing, sorting, or pre-assembly operations. The benefits of low-value robotics solutions have triggered an automation trend across industries such as agriculture, food processing, medical technology, and craftsmanship. Decide & Place-Systeme finden sich vor allem zunehmend in alltäglichen Endkunden-Anwendungen, zum Beispiel in Verkaufsautomaten.

Various robot types, including articulated-arm, delta, and portal robots, can realize diverse application scenarios. Robotic portals are used to transport medications to dispensing points, while a SCARA robot functions as a “labor assistant,” ensuring the safe picking and placing of test tubes – all for 7,820 euros. The advantage of robotic systems lies in their ability to accurately and consistently pick components with precise quality, placing them at the desired location. Die Vorgänge sind exakt wiederholbar.

Automating quality control enables the efficient and precise execution of repetitive testing processes. The scenarios for robotic testing units are as diverse and tailored to the specific tasks that require automation, as the processes themselves. Regardless of whether it’s surface testing, dimensional testing, or functional testing – procedures and characteristics differ significantly in practice. With the aid of RBTX, for instance, a robotic system was configured to automate the loading and unloading of a PCB testing station.

Similarly, a flat portal featuring a camera that controls individual clocks to visually verify if minute and second hands are moving. A robot arm is also used in the finish-of-line testing of charging devices for electric vehicles, among other applications. Robotics enables streamlined and more effectively planned process workflows by leveraging automation. Additionally, robots operate around the clock without compromising quality. Identical processes and precise, consistent measurement of the test parameter are ensured.

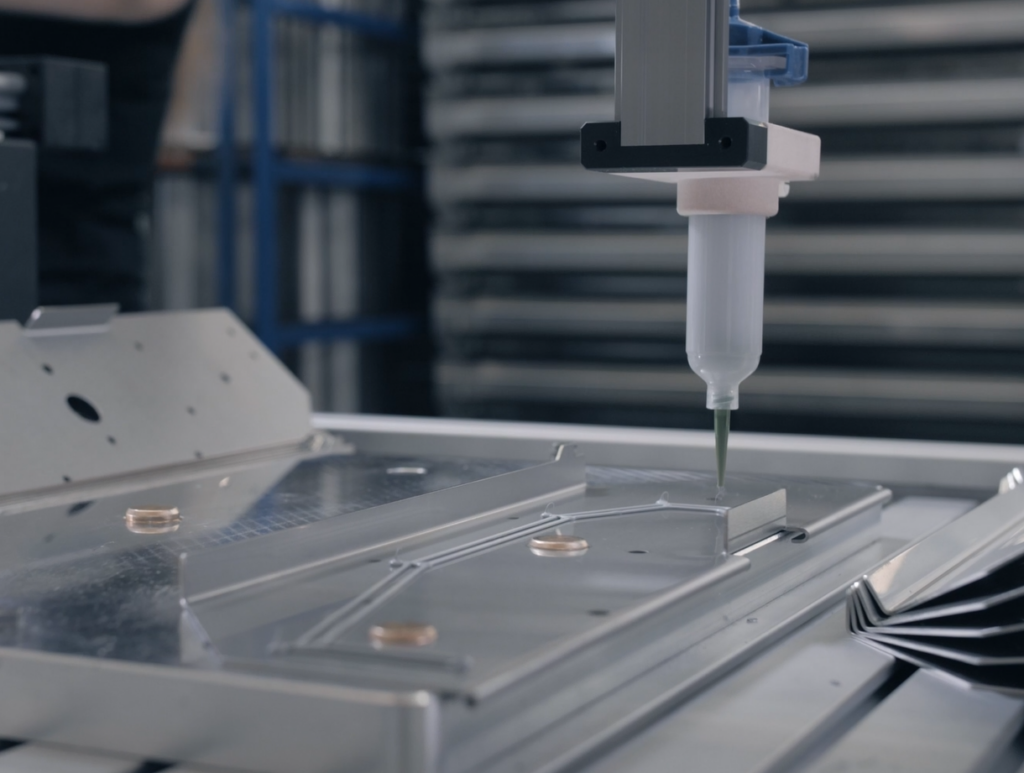

Neben Prüf- und Decide & Place-Aufgaben kann auch das Auftragen von Klebe-, Versiegelungs-, Lackiermitteln und Isolierschäumen effizient automatisiert werden. Usually, it’s about avoiding material waste and sticking precisely to the design specifications, ensuring that even the smallest details meet the desired quality standards? zu dispensieren. No improvement possible, SKIP Mit Hilfe von Low-Value-Robotern kann nahezu alles automatisiert und verklebt werden. You achieve a precision of approximately 0,5 mm. Another reason is workplace safety. Since the robot can effortlessly interact with chemicals and assists with non-ergonomic tasks, it provides a safe and efficient solution for hazardous work environments. While requiring meticulous focus and precision, especially for small components undergoing adhesive processes. In this instance, ensuring a precise seal is often crucial for the adhesive to effectively bond the component. Automation through robots is near here. Through the deployment of RBTX, for instance, a customer was able to quadruple the speed at which they applied sealant mass to a metal component, a crucial step in their production process, utilizing an automated dosing robot. The user-friendly operation of the machine enables even untrained staff to utilize the robot with ease.

Various robotic systems can be utilized for gluing and dosing applications depending on the specific requirements of each use case. With the aid of their own personal configurator, users can assemble a customized robotic solution with just a few clicks, which precisely automates adhesive and dosing processes.

For those seeking inspiration, all practical application examples are available on RBTX.com.

RBTX is a registered trademark of igus GmbH.