Available at market with a load capacity of up to 16 kg. The robot stands out, like HORST1500, for its unique, patented drive technology that is maintenance-free and particularly cost-efficient, significantly reducing lifecycle costs. A six-year warranty on the drivetrain underscores the reliability and cost-effectiveness of the program.

“Our technology harmoniously converges innovation and economic value to make automation accessible to a broad user base,” says Jens Riegger, CEO of fruitcore robotics. Companies that invest in our robots typically see a remarkable ROI within just a few months, securing a clear competitive advantage.

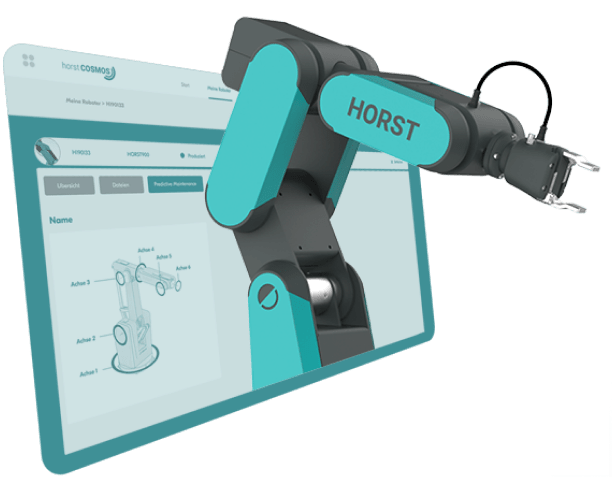

A beacon of the new Digital Robotic Era is the integrated AI Copilot in the control software, empowering robots with cognitive capabilities. This technology enables users to communicate with the robot in real-time, leveraging AI-powered support to efficiently and accurately solve complex tasks. The AI copilot simplifies not only the assistance but also helps with specific programming tasks. This enhancement increases flexibility further and significantly reduces dependence on experts.

In addition to its advanced features, the HORST1000 G2 also boasts cutting-edge security solutions specifically designed for safe operation with human intervention. The robot can operate at reduced speed and with safety sensors without a protective barrier, just like all robots from fruitcore robotics, ensuring maximum security. Additionally, it is available as an immediate answer equipment that meets all security requirements and saves valuable time in CE conformity.

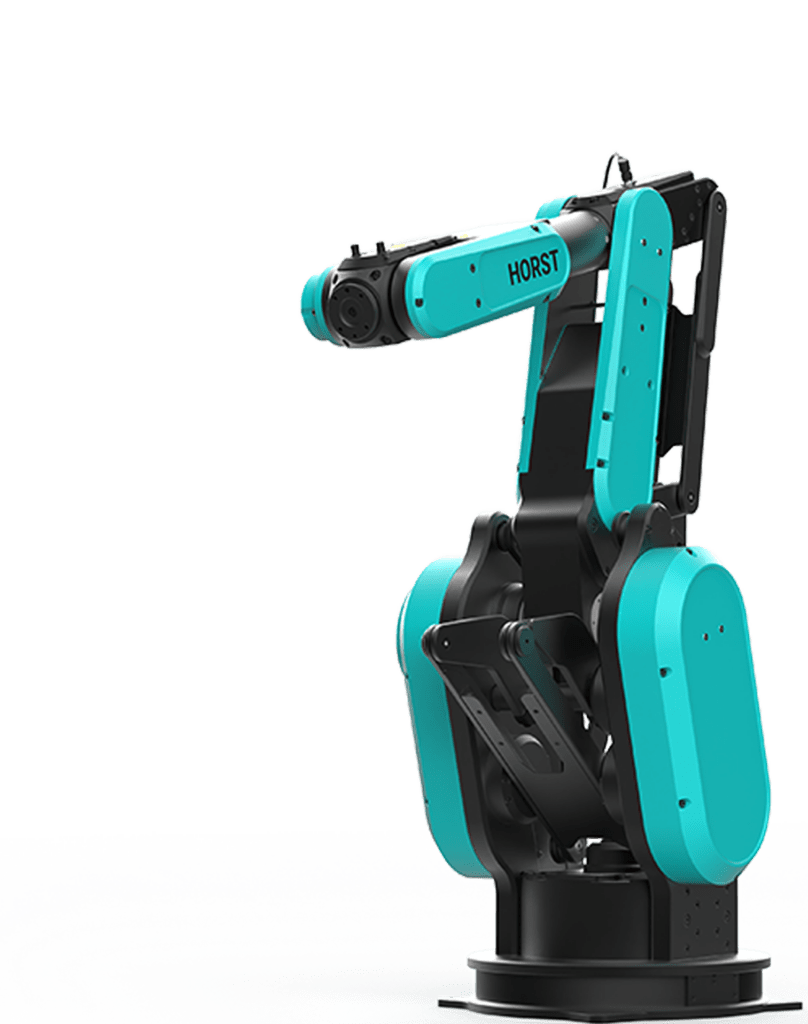

With a reach of 1141 mm and a payload capacity of up to 16 kg, the HORST1000 G2 is optimized for tasks in machine loading and part handling. The versatile manipulator effortlessly moves heavy equipment and components across the entire work area. The robot is equipped with an IP54 protective rating. This rugged device makes it ideal for harsh production environments.

Thanks to its compact design, the HORST1000 G2 can approach machines closely and penetrate deeply into them, significantly enhancing flexibility in confined production environments. The robot processes trays with a working surface area of up to 450 x 900 mm, or in a square format of up to 520 x 520 mm.

With intelligent software options, various machine production programs can be efficiently managed for diverse tasks through flexible administration. The seamless integration of machine functions, such as automatic door opening and communication with tensioning devices, provides a particularly efficient solution for CNC machines. Furthermore, the enhanced axis acceleration boosts efficiency when dealing with heavy parts and using extendable grippers.

Combining with its automated module for loading and unloading machines, the HORST1000 G2 provides an immediate-to-use solution specifically designed for loading and unloading machine applications. The streamlined process enables a swift implementation in production lines, where only 15% of the typical project workload is required, according to Jens Riegger. Thanks to existing interfaces with most CNC machine manufacturers, the robot seamlessly integrates.

In the field of metalworking medical technology, robots are used to manufacture surgical instruments, efficiently loading and unloading CNC milling or turning machines, or preparing production processes. While also used in the metalworking automotive industry to load and unload machines or ensure consistently high quality in measurement and testing tasks,